Dry Ice Blaster Machine Working Principle

The Dry Ice Blasting Machine uses compressed air as its power source to accelerate dry ice particles to supersonic speeds, which are then blasted onto the surface of the object to be cleaned. Unlike cleaning methods that rely purely on the kinetic energy of the dry ice particles, the dry ice blasting equipment also utilizes the extremely low temperature of dry ice to enhance its cleaning effect. When the dry ice particles collide with the surface, they sublimate rapidly upon impact. This process generates a swift heat exchange, causing the solid carbon dioxide in the dry ice to sublimate into gas, expanding nearly 800 times in volume. This rapid expansion creates a “micro-explosion” effect, which effectively removes surface contaminants, resulting in a thorough cleaning.

Why Choose Dry Ice Blaster Machine?

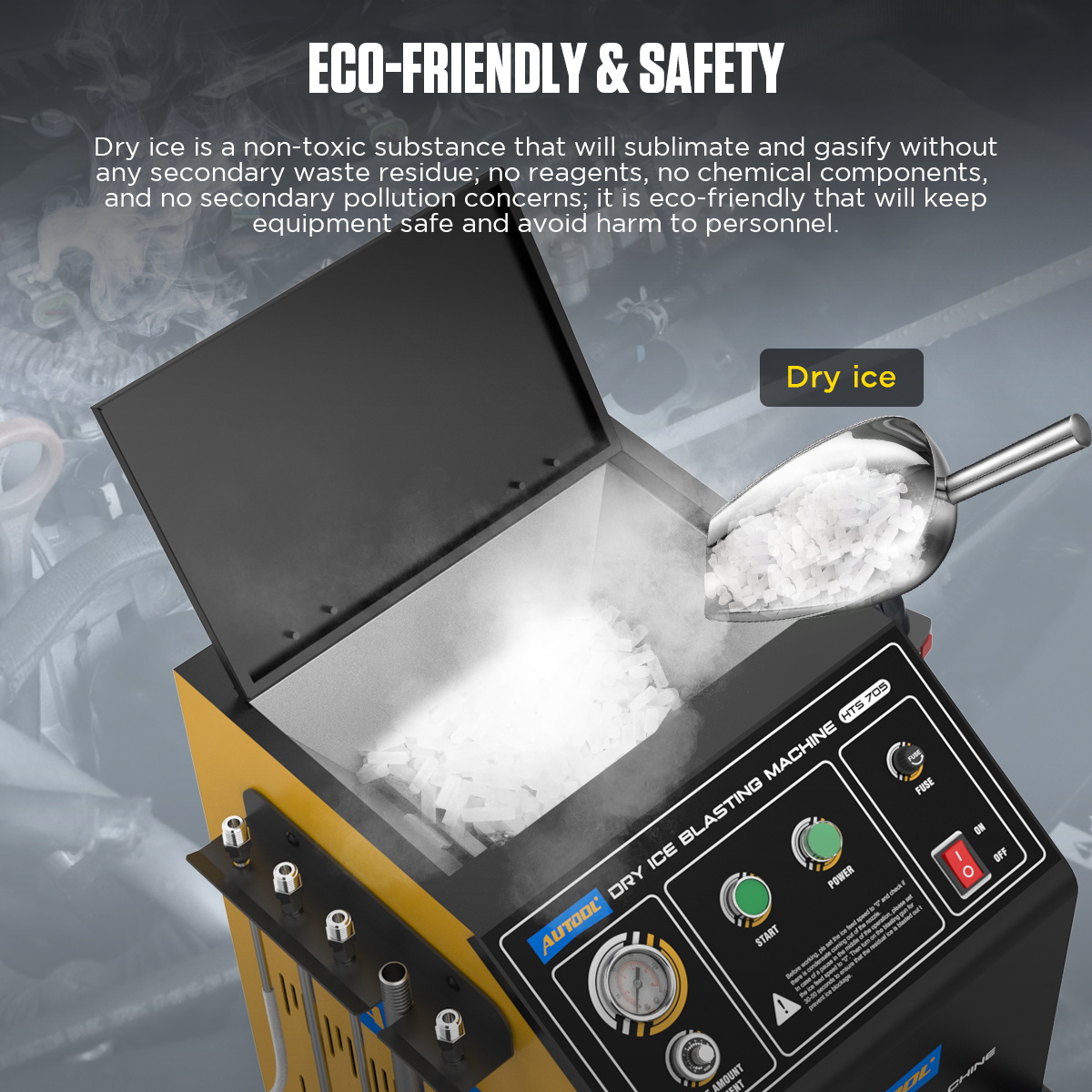

Dry ice cleaning offers several key advantages over traditional cleaning methods like chemical solvents, hydrogen-oxygen machines, and walnut blasters. First, it does not require engine disassembly. Second, compared to hydrogen-oxygen machine cleaning, dry ice cleaning is a physical carbon removal process that does not damage sensitive vehicle components such as the catalytic converter. Third, unlike walnut blaster cleaning, dry ice cleaning causes no wear on the parts being cleaned. The carbon deposits are rapidly turned into powder through the impact and explosion of high-pressure air and -78.5°C dry ice particles. Finally, the dry ice sublimates and decomposes, with impurities being expelled from the engine via compressed air. This entire process is non-toxic, harmless, and free from secondary pollution.

AUTOOL HTS705 Dry Ice Blaster Machine Features

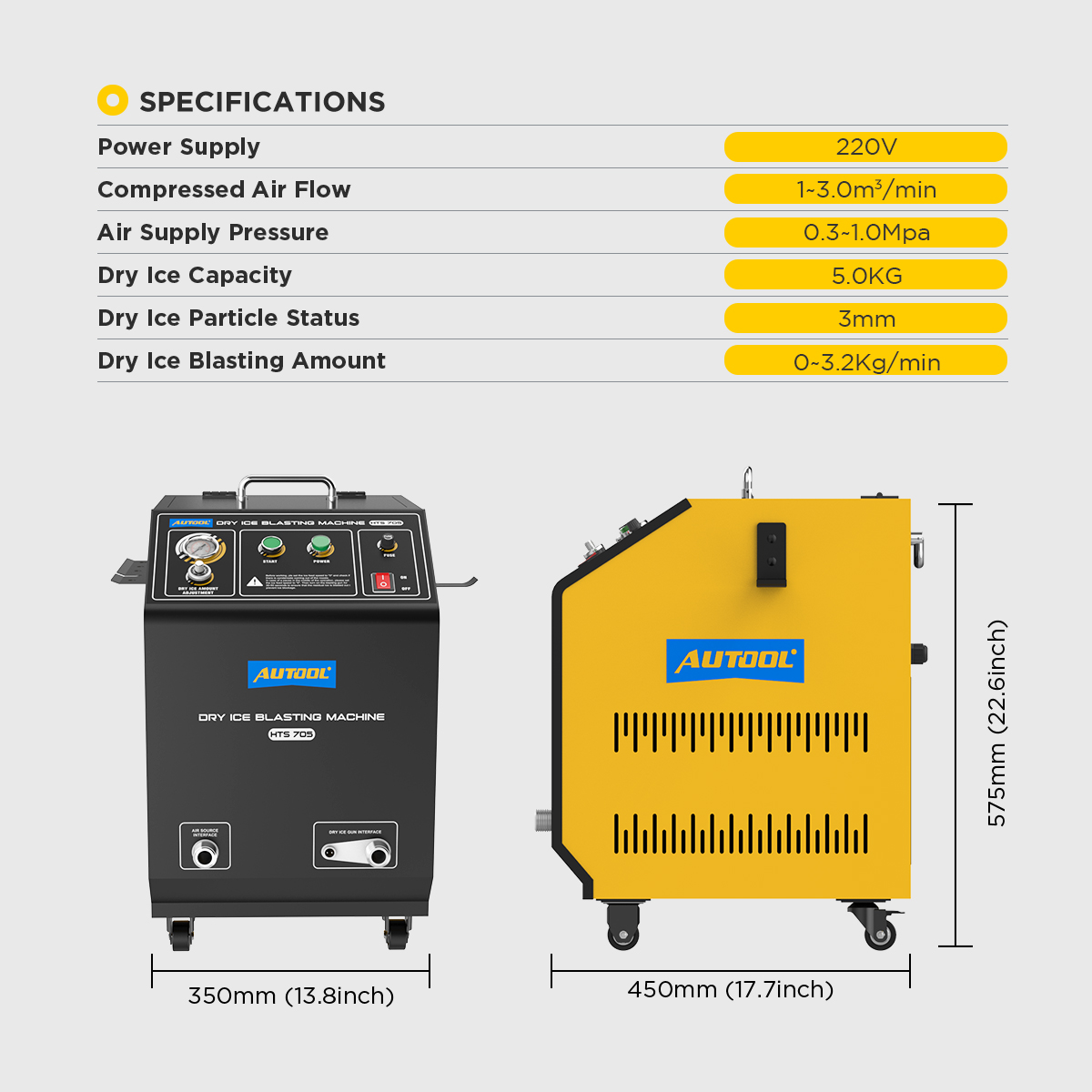

High-power air filtration system: Equipped with an efficient air filter, it effectively prevents moisture from entering the engine block, ensuring the purity of the dry ice, avoiding condensation, and preventing ice blockages in the pipes.

Spiral Ice Separation Technology: The innovative spiral dry ice separation system continuously stirs to prevent dry ice from sticking together or forming clumps, ensuring smooth delivery of dry ice particles during the cleaning process and avoiding any blockages.

Control panel: Equipped with an integrated smart microcomputer, it allows precise control of pressure and enables free adjustment of both pressure and speed.

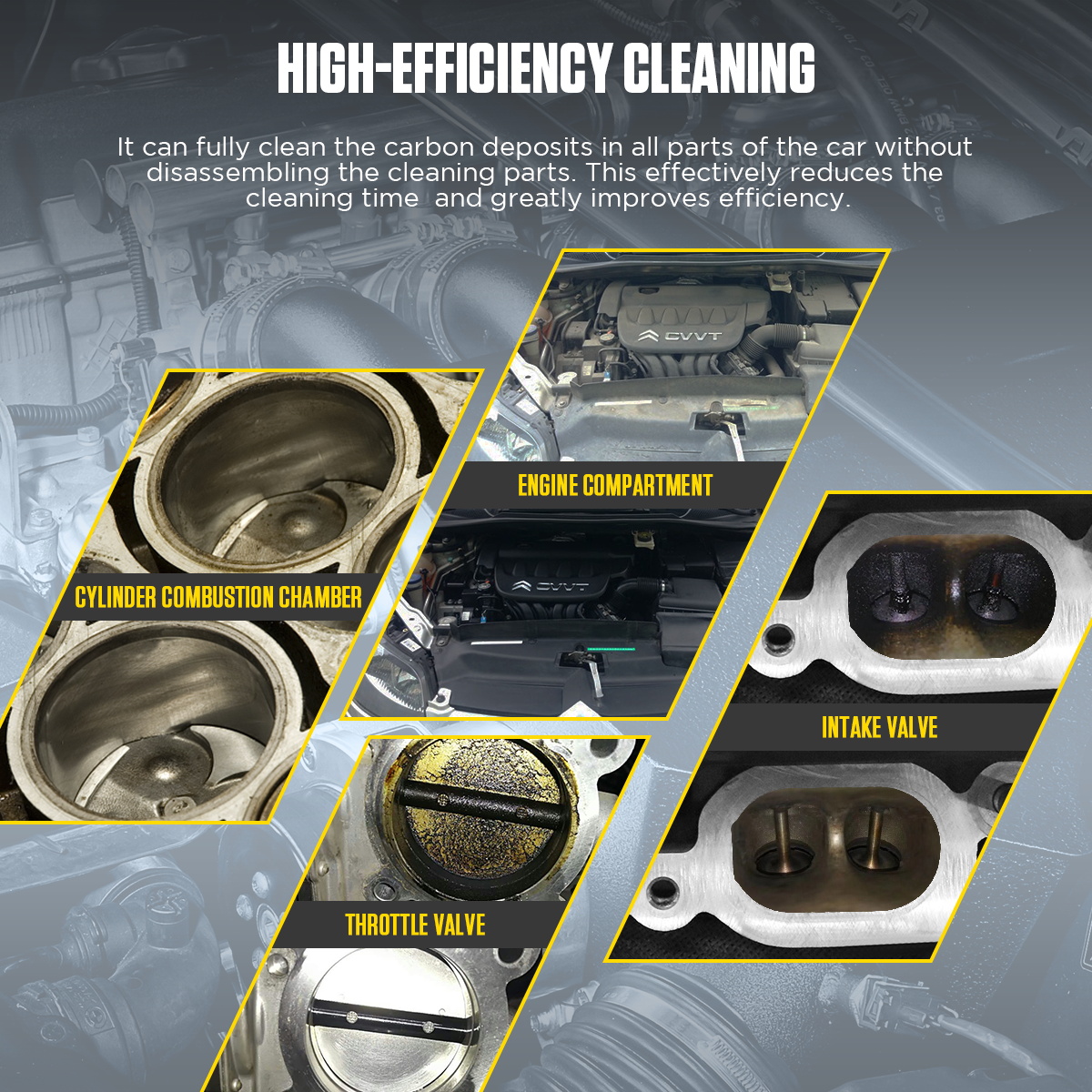

Efficient Cleaning: No need to disassemble vehicle components. In about 15 minutes, carbon deposits in various vehicle parts (such as the throttle, intake valves, engine components, and cylinder combustion chambers) can be thoroughly cleaned.

Safe and Harmless: Dry ice is a non-toxic, harmless substance, ensuring the safe use of the equipment and preventing harm to users’ health.

Exquisite design: The equipment is equipped with a push handle, control panel, air source interface, and four universal wheels at the bottom that allow 360° all-around movement, making it convenient and labor-saving.

Wide Application Range: It is widely used in various industries such as rubber, casting, automotive, shipping, power, chemicals, printing, plastics, food, pharmaceuticals, aviation, and more, not limited to automotive maintenance.

Three-Year Warranty, Lifetime Maintenance: For damage caused by non-human factors, AUTOOL promises to resend parts for free within 3 years. If you have any problems, please contact us, and we will respond within 24 hours!

AUTOOL HTS705 Dry Ice Blaster Machine Operating Instructions

Step 1: Equipment Debugging

1. Connect the main unit to the external air and power sources, check whether the air pressure indicator data is normal, and verify that the power connection is correct (ensure the power is properly grounded).

2. Prepare the machine for testing, correctly connect the machine and accessories, check for any loose components, and remove unnecessary items from the machine or workspace.

3. Turn on the power switch and set the machine to the start mode. Press the start button on the handle to begin operation. Adjust the dry ice quantity from 0 to maximum, check for any abnormalities, and perform a trial run with dry ice loaded into the machine.

Step 2: Adjusting Dry Ice Blasting Amount

1. Add the appropriate amount of dry ice and secure the lid.

2. Use the controller to adjust the dry ice blasting amount to achieve the desired cleaning effect (start from “5” and adjust based on the cleaning result).

3. If using a smaller diameter tank, initially set it to “3” and then adjust as needed.

4. After confirmation, aim the spray nozzle at the part to be cleaned, press the start button on the handle, and begin the cleaning process.

Step 3: Completing the Cleaning Operation

1. Adjust the dry ice amount controller to “0” and operate the spray nozzle for 30-50 seconds until no water is expelled.

2. If dry ice residue remains, extend the spraying time. Manual cleaning may be required if necessary.

3. Turn off the power switch, disconnect the air source, and store the spray nozzle and accessories.

Tips:

1. The Dry Ice Blaster Machine must be used in conjunction with an air compressor, but the air compressor is not included in the package. The cleaning effect is determined by the air pressure output from the air compressor, not by horsepower (HP).

2. It is recommended that the air compressor have a power of 7.5kW or higher and an air tank capacity of 300L or more to ensure optimal performance and stable operation of the Dry Ice Blasting Machine.

3. The recommended size for dry ice particles is 3-5mm.

4. Cleaning an automobile engine will typically require about 15KG of dry ice.