AUTOOL LM707 Freon Recovery Machine

Vacuuming: Utilizes a vacuum pump to remove air and moisture from the refrigeration system, ensuring no impurities affect the refrigerant flling process.

Refrigerant Filling: Uses a flow control valve and pressure sensor to precisely transfer refrigerant from the storage tank into the refrigeration system, completing the filling process according to the preset amount.

Smart Monitoring: Real-time monitoring of pressure and flow to prevent overfilling or insufficient filling. Automatic shutoff and alert for abnormal conditions.

Safety Protection: Continuous monitoring of temperature and pressure to prevent refrigerant leakage or overpressure, ensuring the safety of the equipment and operators.

The core lies in vacuuming, precise filling, and intelligent control, achieving an efficient, safe, and environmentally friendly refrigerant filling process.

AUTOOL LM707 Freon Recovery Machine Features

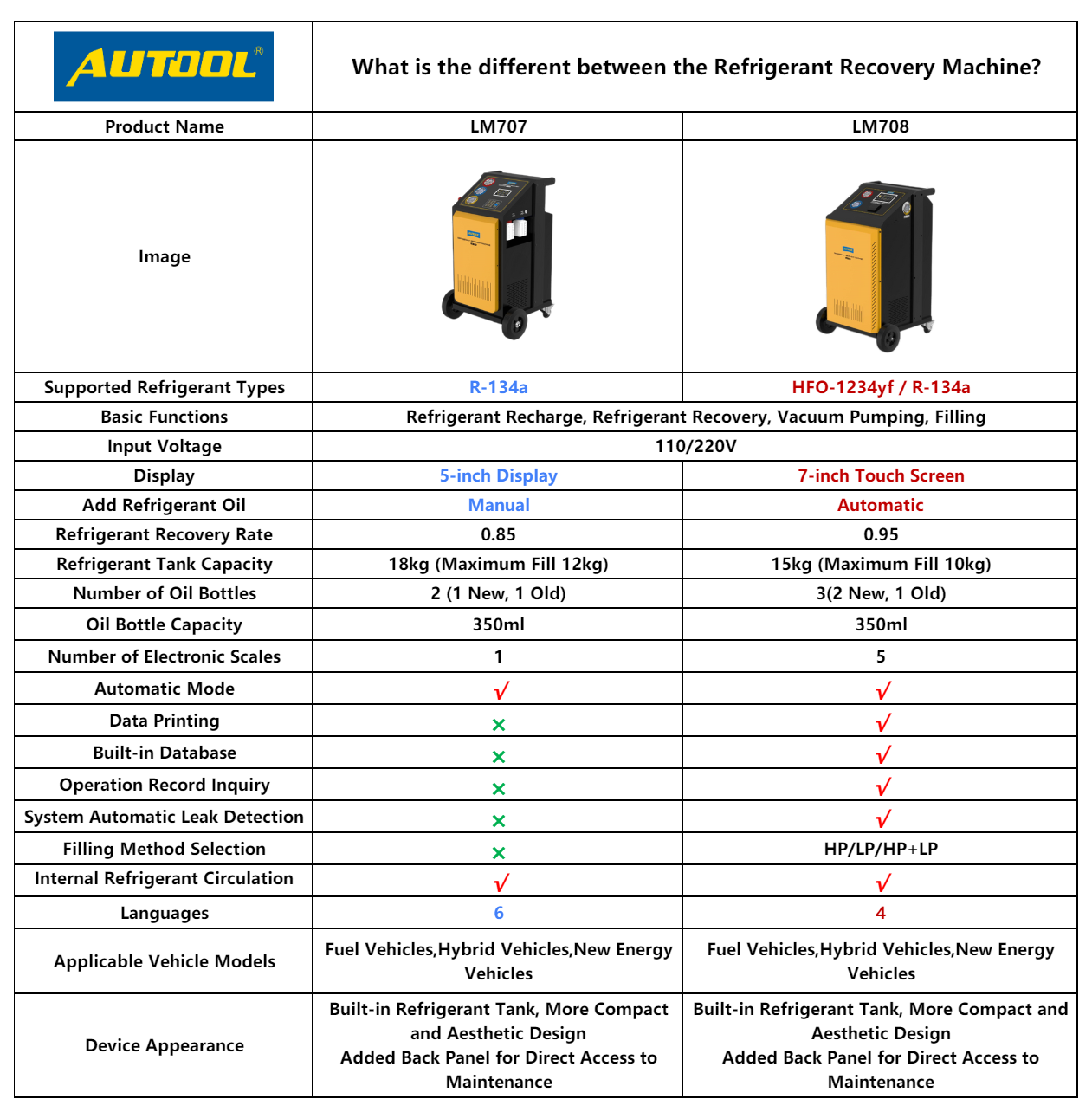

Built-in Database: Equipped with data for various vehicle models, allowing for selection and automatic matching of the corresponding refrigerant type and fillling amount based on the vehicle model. No more worries about selecting refrigerant information for vehicles.

Wide Compatibility: The LM707 freon recovery machine features a patented pipieline design, ensuring high efficiency in both gas pump recovery and liquid recovery.

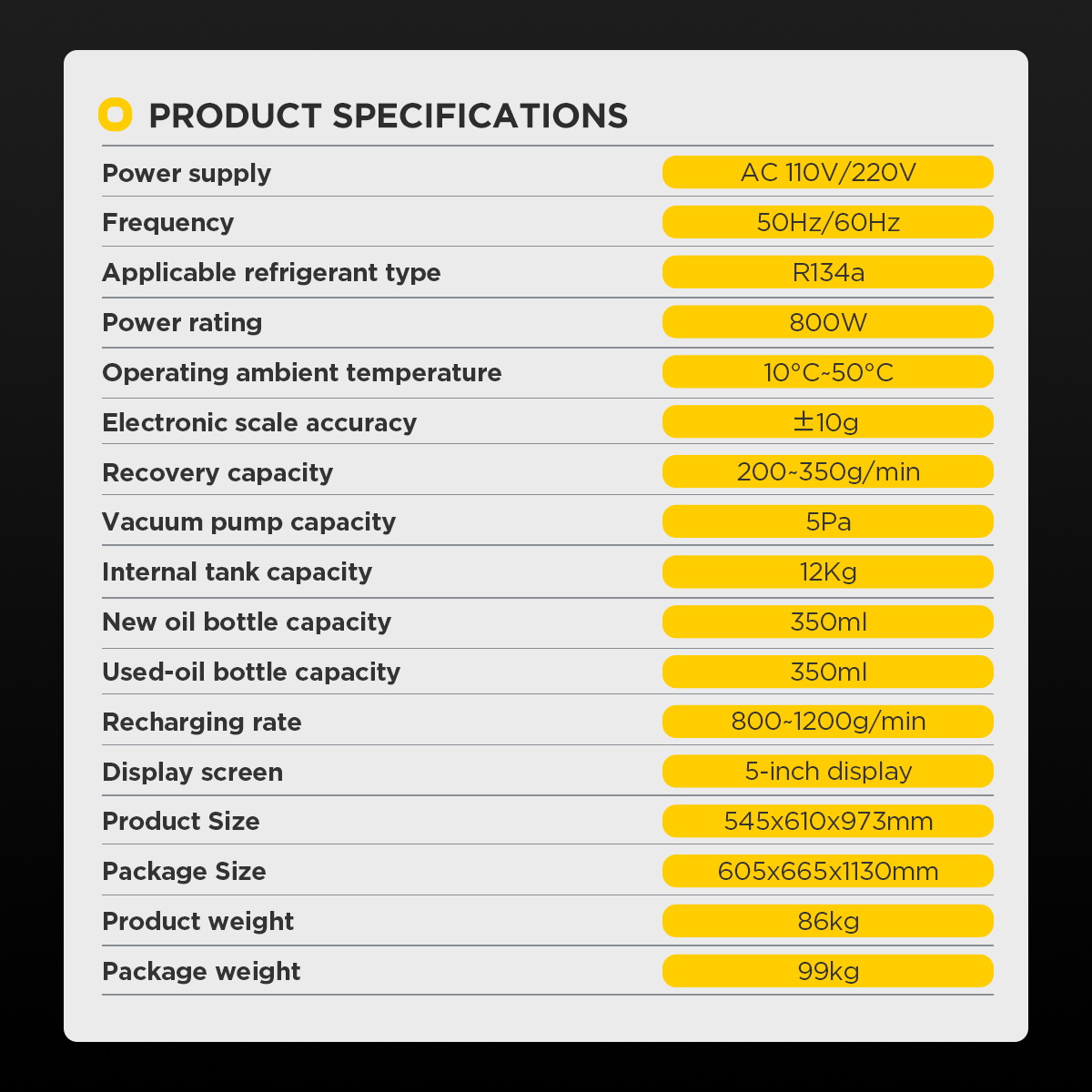

Large Capacity Internal Tank: The refrigerant tank can store up to 12 kg of refrigerant, enabling continuous refrigerant replacement for dozens of vehicles.

High-Precision Electronic Scale: Equipped with a high-precision electronic scale to accurately measure refrigerant weight, enabling precise refrigerant recovery and filling.

Fully Automatic LM707 Electronic Refrigerant Filling Machine: Parameters can be preset, and the machine completes tasks according to instructions, achieving full automation of the entire operation process, significantly improving work efficiency.

Self-Protection Function: The LM707 fully automatic refrigerant filling machine features a self-protection function, automatically stopping and alerting in case of issues during the replacement process, greatly ensuring the safety of the equipment and vehicle.

AUTOOL LM707 Freon Recovery Machine Operating Instructions

Check the equipment and air conditioning system status to ensure that connections are secure and there are no leaks.

Start the vacuum gauge and select the appropriate vacuum unit.

Connect the vacuum gauge to the system interface and start the vacuum pump.

Monitor the vacuum value in real time to ensure it reaches the standard vacuum level.

Stop the vacuuming process and observe the data stability to assess the system’s sealing.

Once completed, turn off the equipment, disconnect, and store it properly.