Working Principle

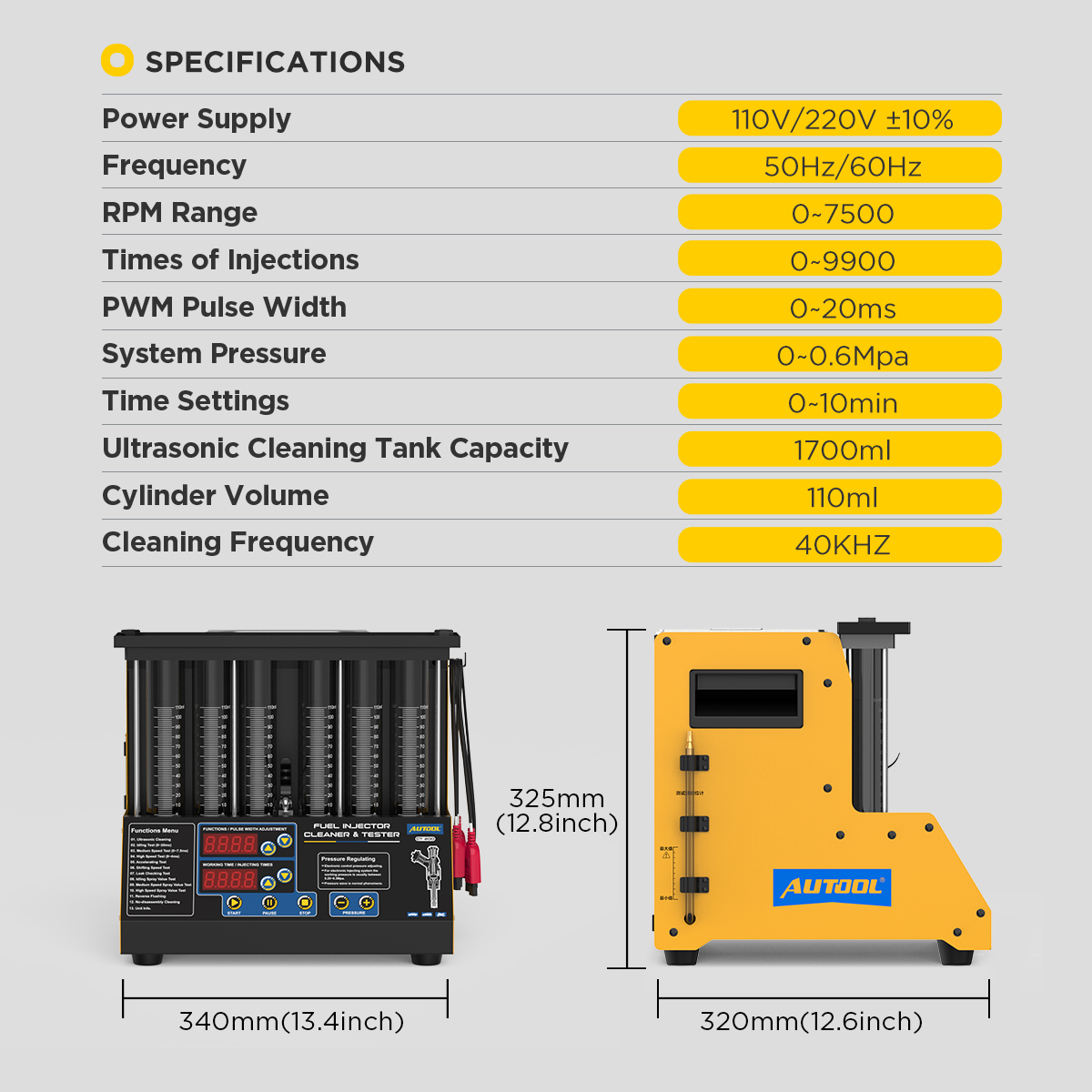

The AUTOOL CT200 Fuel Injector Tester & Cleaner integrates ultrasonic cleaning technology with microcomputer-controlled fuel pressure closed-loop control. The built-in microcomputer control unit precisely monitors and dynamically adjusts the fuel pressure, simulating various engine operating conditions such as idle and high-speed modes. The ultrasonic cleaning technology effectively removes carbon deposits and oil sludge from the interior of the fuel injectors, while the closed-loop control system ensures stable and continuous fuel pressure for highly accurate testing. This combination of cleaning and performance testing significantly enhances the cleaning efficiency and overall performance of fuel injectors.

AUTOOL CT200 Fuel Injector Tester & Cleaner Features

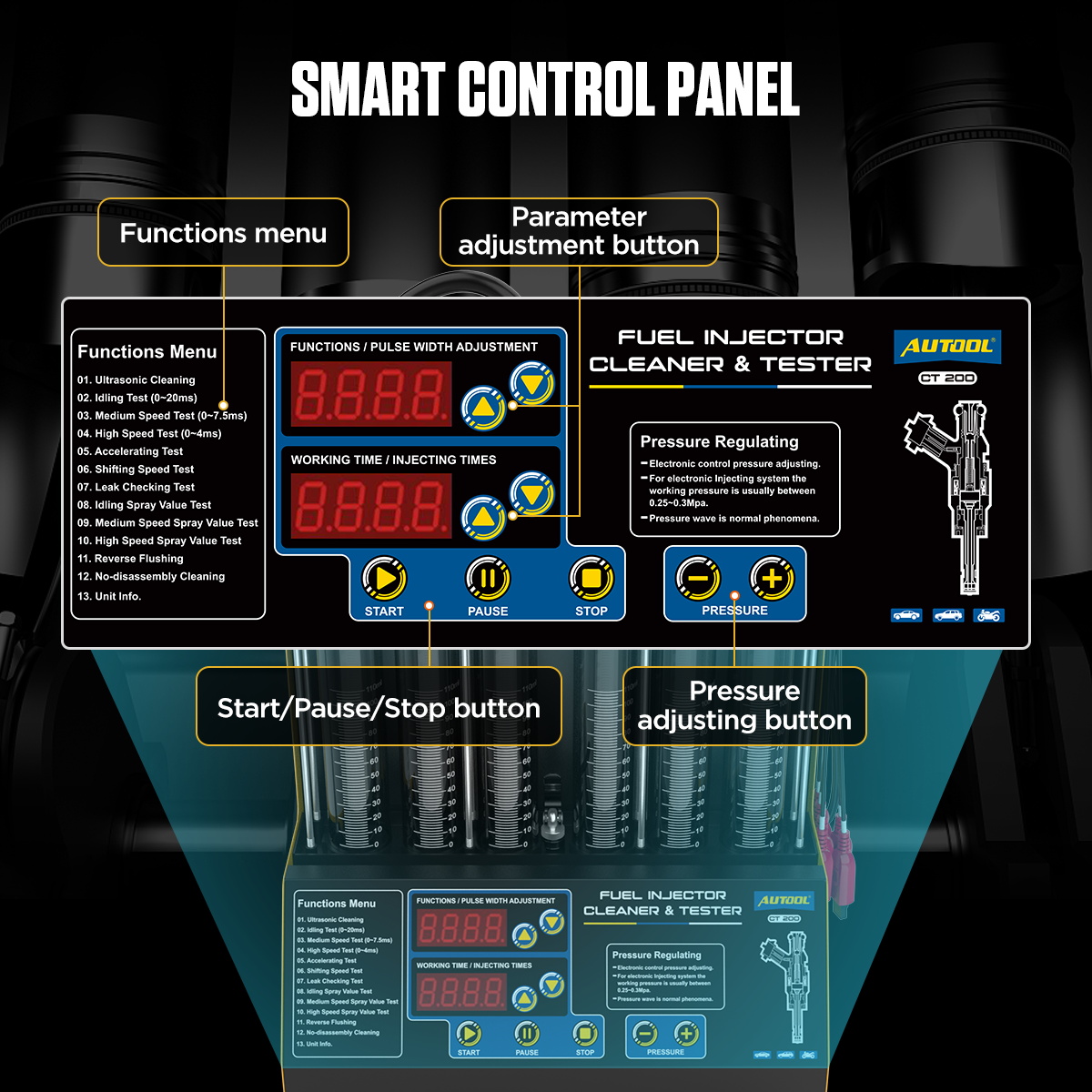

9 Testing Functions

Idle Speed Test (0-20ms): Simulates engine idle speed operation to test the performance of the fuel injectors.

Medium-Speed Test (0-7.5ms): Simulates engine mid-speed operation to test the fuel injector performance.

High-Speed Test (0-4ms): Simulates engine high-speed operation to test the performance of the fuel injectors.

Acceleration Test: Simulates vehicle’s acceleration state to test the working performance of the fuel injectors.

Shift Speed Test: Simulates the vehicle’s gear-shifting state to test the working performance of the fuel injectors.

Leakage Check Test: Tests the sealing integrity of the fuel injectors.

Idle Spray Volume Test: Simulates the engine’s idle state to assess the atomization performance of the fuel injectors.

Medium-Speed Spray Volume Test: Simulates the engine’s medium-speed state to assess the atomization performance of the fuel injectors.

High-Speed Spray Volume Test: Simulates the engine’s high-speed state to assess the atomization performance of the fuel injectors.

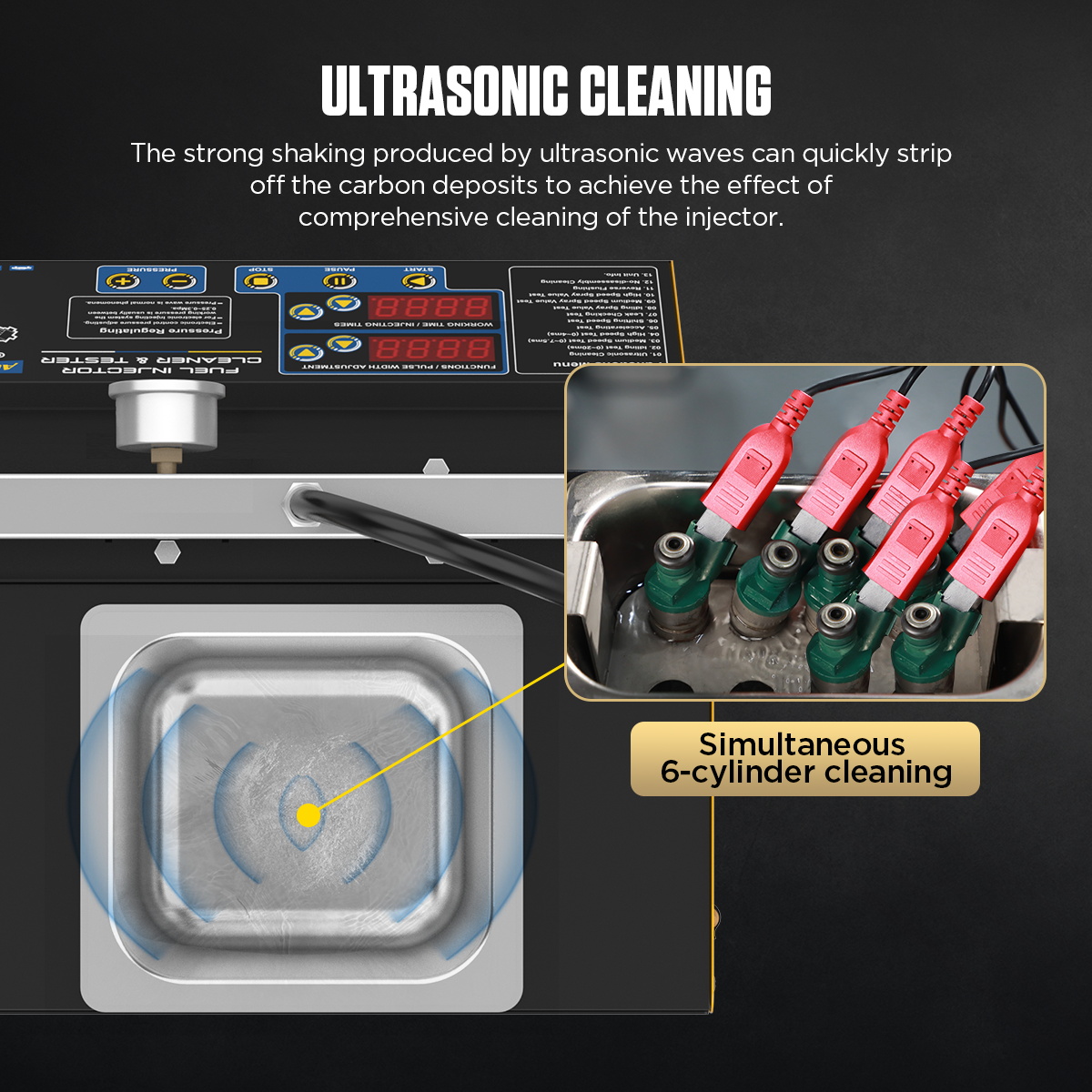

Ultrasonic Deep Cleaning: The CT200 injector ultrasonic cleaner utilizes pulse signal cables to send signals to the fuel injectors, combined with cleaning fluid and ultrasonic vibration technology. This process efficiently removes carbon deposits and stubborn impurities inside the fuel injectors, ensuring thorough and deep cleaning.

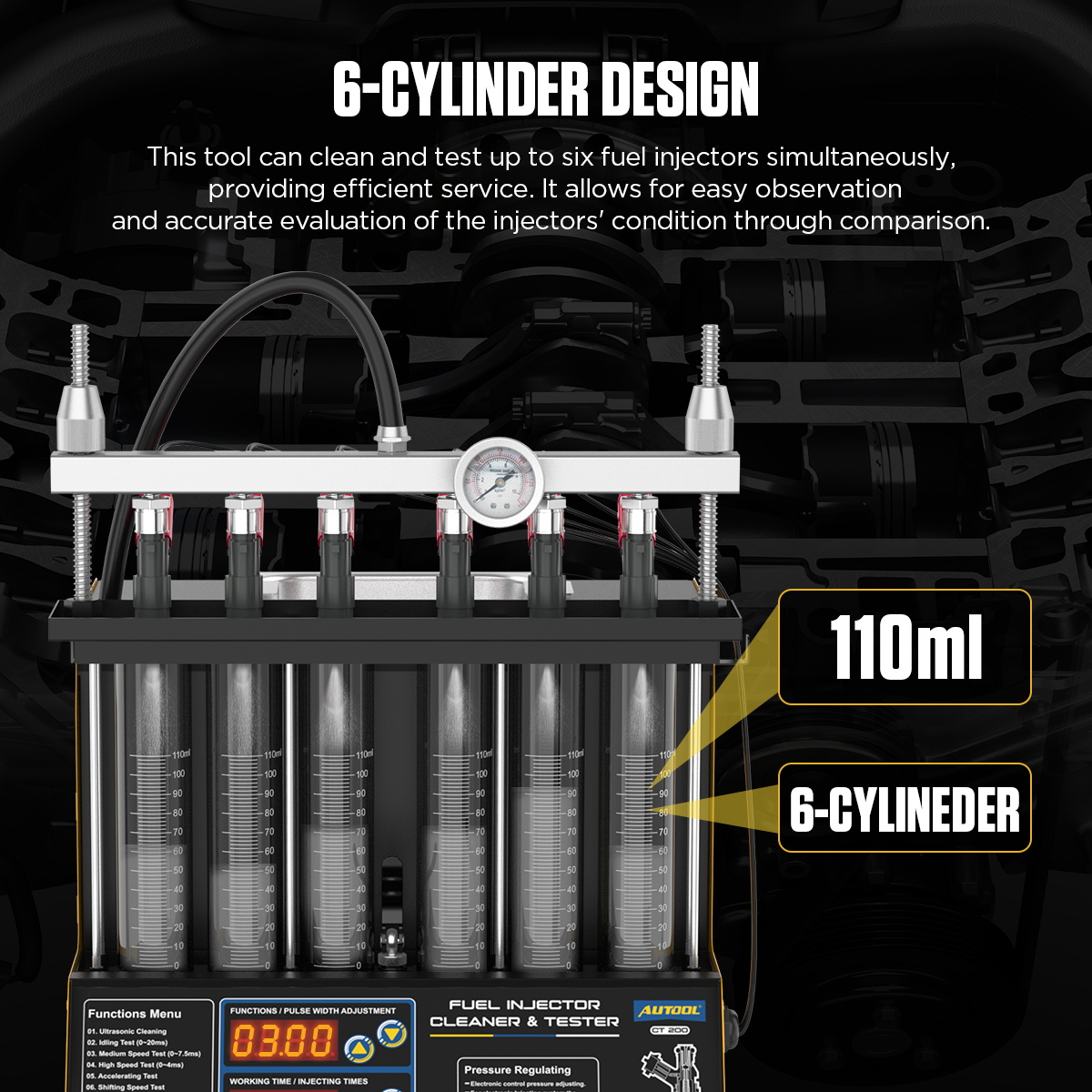

Multi-Injector Cleaning and Testing: The CT200 Fuel Injector Tester & Cleaner features six independent glass tubes, enabling the simultaneous cleaning and testing of up to six injectors. This greatly enhances cleaning efficiency, streamlines the testing process, and ensures more convenient operation.

Reverse Cleaning Function: The AUTOOL CT200 GDI fuel injector tester utilizes cleaning fluid injected from the nozzle’s outlet to the inlet, effectively removing internal deposits and filter impurities. This feature is particularly suitable for top-feed fuel injectors, significantly enhancing the cleaning performance (only applicable to top-feed fuel injectors).

Non-disassembly Cleaning Function: With the help of a dedicated adapter, the fuel injectors can be cleaned directly without disassembly, making it convenient and quick, offering an additional cleaning option (this function requires the optional non-disassembly cleaning tool).

Stable and Reliable Pressure: The equipment uses advanced electronic pressure regulation technology to ensure that the fuel pressure remains stable and precise at all times. It is equipped with a high-quality fuel pump, ensuring reliable performance and supporting long-term stable operation of the equipment.

Intuitive Display Function: Equipped with a liquid level gauge for precise indication of the added test fluid volume, ensuring accurate test results. The pressure gauge provides real-time monitoring of test pressure, effectively preventing excessive pressure from damaging the equipment or injectors, ensuring safer and more reliable operation.

Flexible Operation: The equipment allows free adjustment of the injector testing time, working frequency, injection count, and shortest switch cycle within an adjustable range, easily adapting to various cleaning and testing needs to meet different operational requirements.

Convenient Liquid Recovery: Equipped with dual liquid recovery valves for efficient collection of test fluid and cleaning fluid, effectively preventing potential damage from prolonged liquid residue. The recovered liquids can be reused, protecting the equipment and reducing operational costs, making it both economical and environmentally friendly.

Wide Application: Equipped with interchangeable composite connectors suitable for a variety of vehicle models, it supports testing and cleaning of almost all gasoline vehicle injectors on the market.

Operating Instructions

Tips:

Please use professional engine carbon cleaning fluid as the ultrasonic cleaning liquid to ensure effective cleaning and equipment safety.

When performing fuel injector testing, select professional test fluids and avoid using corrosive liquids. It is recommended to use anhydrous alcohol as the preferred option.

After use, promptly drain all fluids from the equipment and clean it properly to extend the machine’s lifespan.

Operating Instructions

Ultrasonic Cleaning:

Clean the exterior of the injector with cleaning liquid before turning on the machine.

Once the exterior of the injector is free of dirt, place the injector into the ultrasonic cleaning tank.

Add cleaning liquid, ensuring that the liquid level does not exceed the connection port of the pulse pipeline

Connect the pulse signal wire and select the first ultrasonic cleaning function to start.

Allow the ultrasonic cleaning function to run for deep cleaning.

After cleaning, recover the remaining cleaning liquid.

Fuel Injector Test

Secure the injectors onto the main unit and test the injector’s resistance, short circuit, and current.

Fill half of the glass tube with the testing solution.

Perform leak tests, spray mode tests, and flow rate tests on the flow bench.

Finally, place the injectors back onto the flow bench and retest all functions.