Working Principle

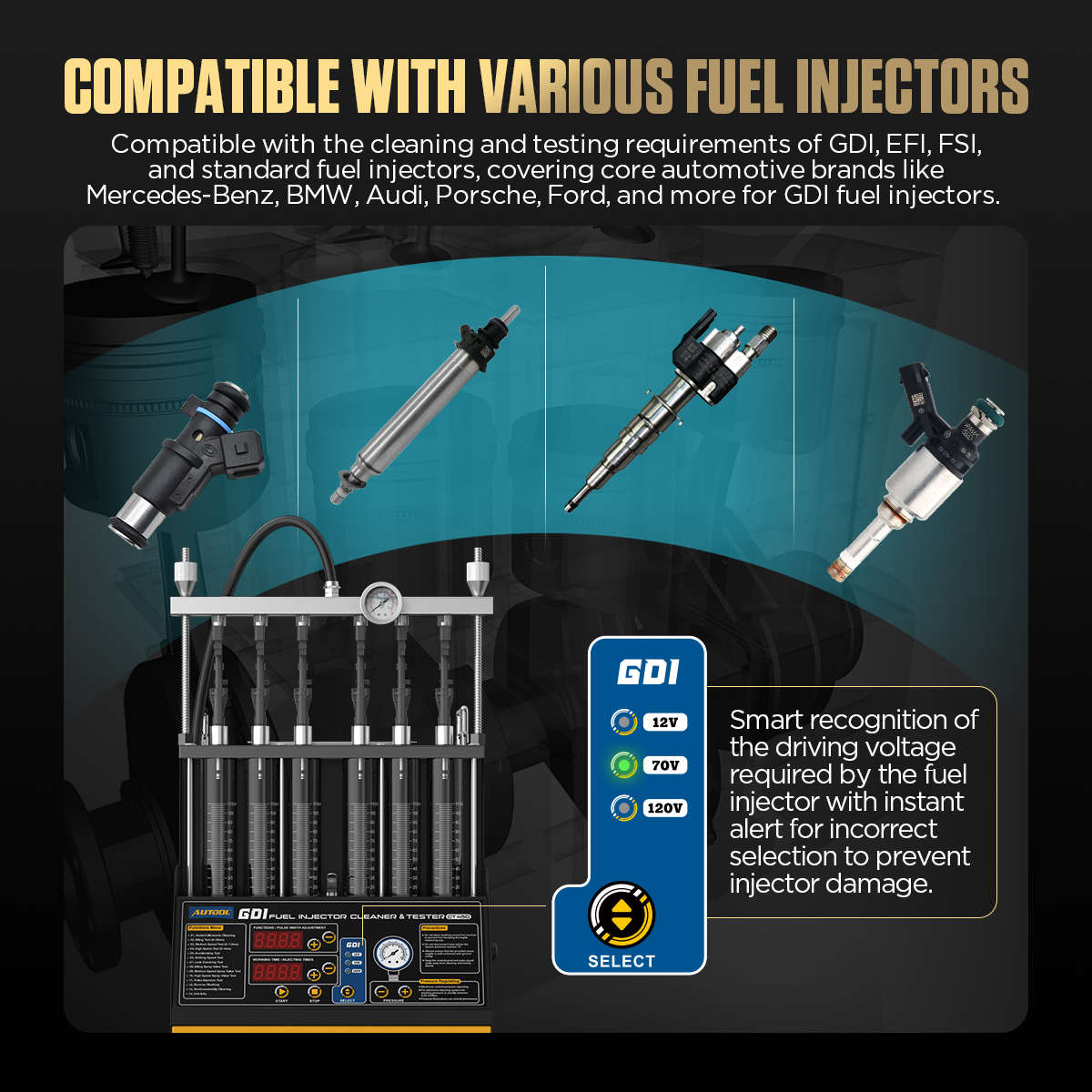

The AUTOOL CT450 GDI Fuel Injector Cleaning Machine utilizes advanced GDI injector driving technology, precisely simulating the operation of gasoline direct injection (GDI) engines. GDI involves injecting fuel directly into the cylinder, where it mixes with intake air. Compared to traditional injection systems, this not only significantly enhances engine efficiency and power output but also effectively reduces exhaust emissions. The CT450 is equipped with an integrated GDI injector driving system that supports the cleaning and testing of various injector types, including GDI, EFI, FSI, and standard injectors. The equipment offers three voltage driving modes (12V, 70V, 120V) to meet the diverse needs of fuel injectors from mainstream automotive brands in Europe, America, and Asia, showcasing excellent compatibility and performance advantages.

AUTOOL CT450 Injector Cleaning Machine Features

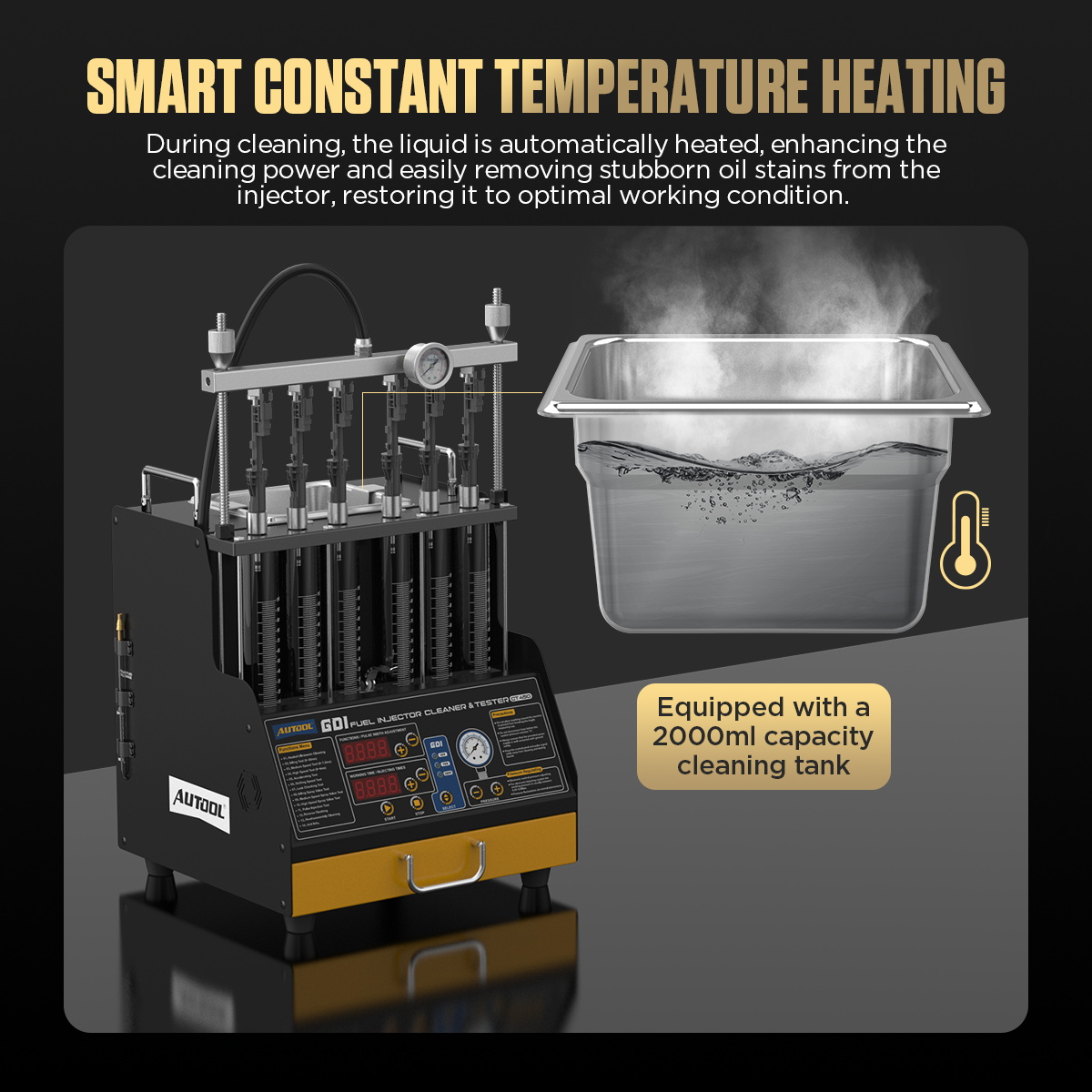

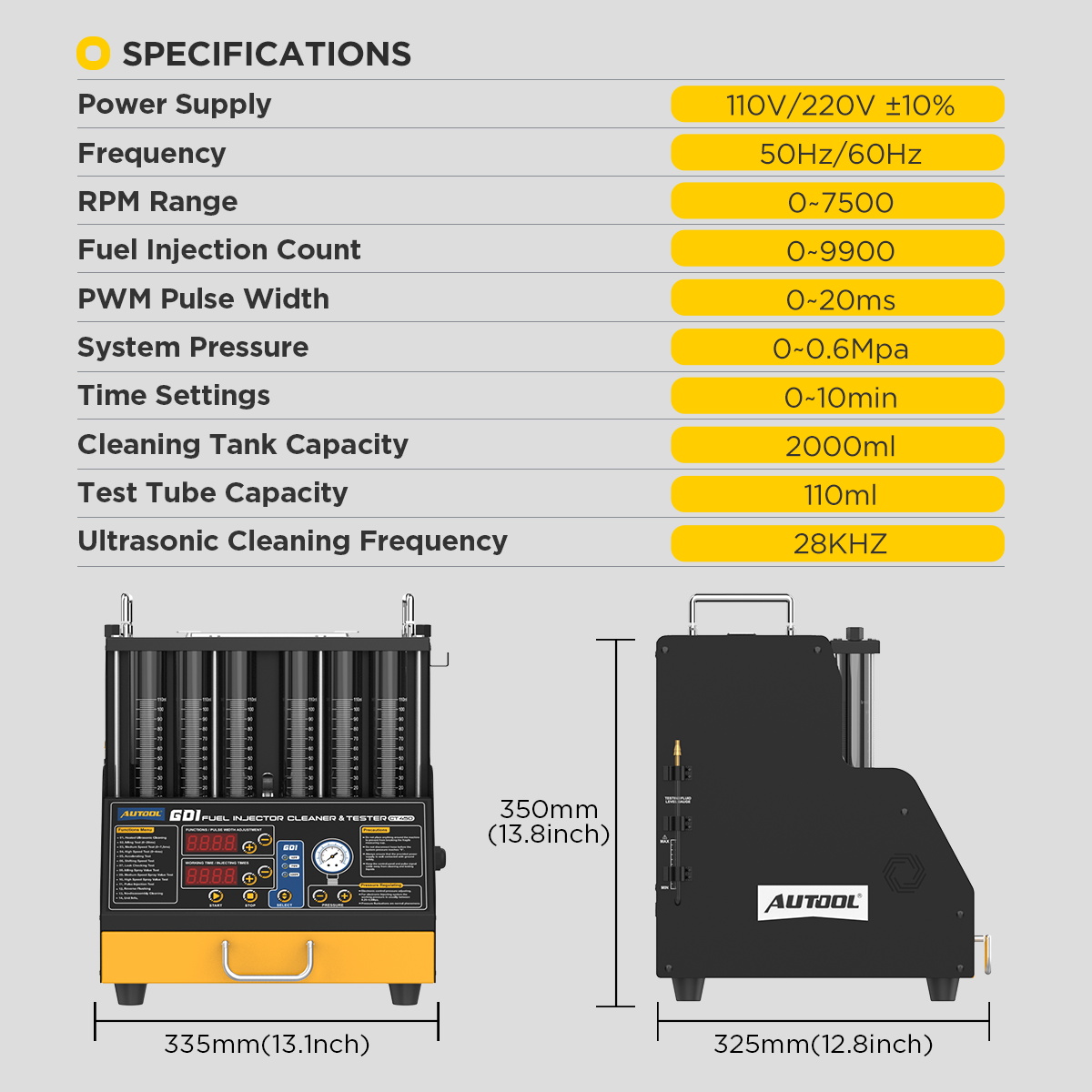

Cleaning Fluid Heating Function: The CT450 Injector Cleaner has a built-in intelligent thermostat function that quickly heats 2000ml of cleaning solution to 50℃ and maintains that temperature.

Wide Range of Adaptations: Equipped with 9 adapters, adapters specifically for BMW injectors, and connectors for different sizes of automotive injectors, it is capable of testing most automotive injectors on the market.

Protects Injectors: The self-protection function protects injectors from damage when detecting GDI injectors.

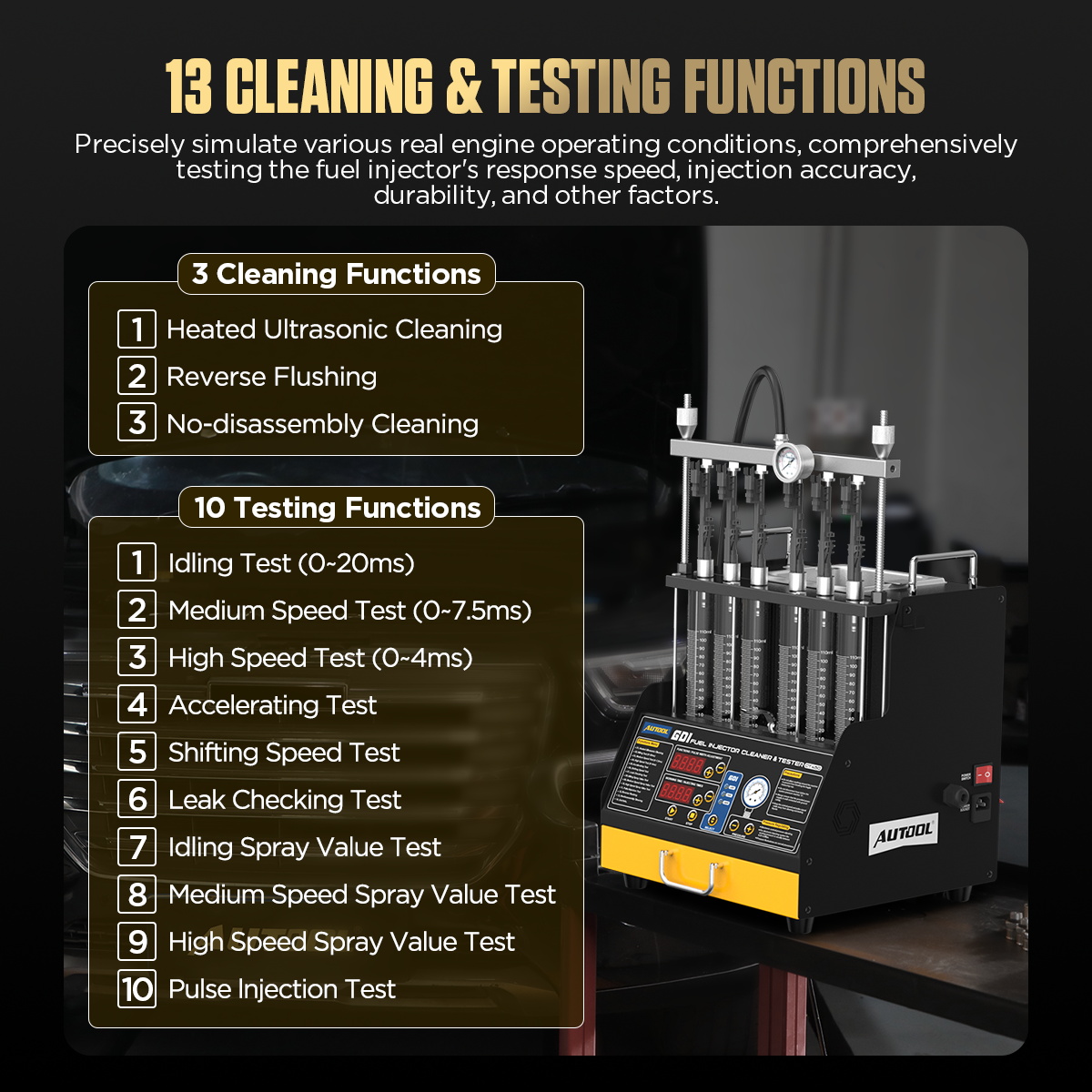

Comprehensive Functionality: The AUTOOL CT450 Injector Cleaner offers 3 cleaning modes and 10 test functions for efficient cleaning and thorough diagnostics to ensure optimal performance of automotive injectors.

High Cleaning Efficiency: With 28kHz high-frequency ultrasonic cleaning and 50°C heating, the system effectively removes oil, carbon and gelatinous residues from automotive injectors, ensuring a fast and thorough cleaning process.

Multi-voltage Selection: The CT450 provides adjustable voltage output (12V, 70V, 120V) for different injectors. It intelligently recognizes the required drive voltage for GDI injectors, preventing damage due to incorrect settings and avoiding fuel injection or alarm signals.

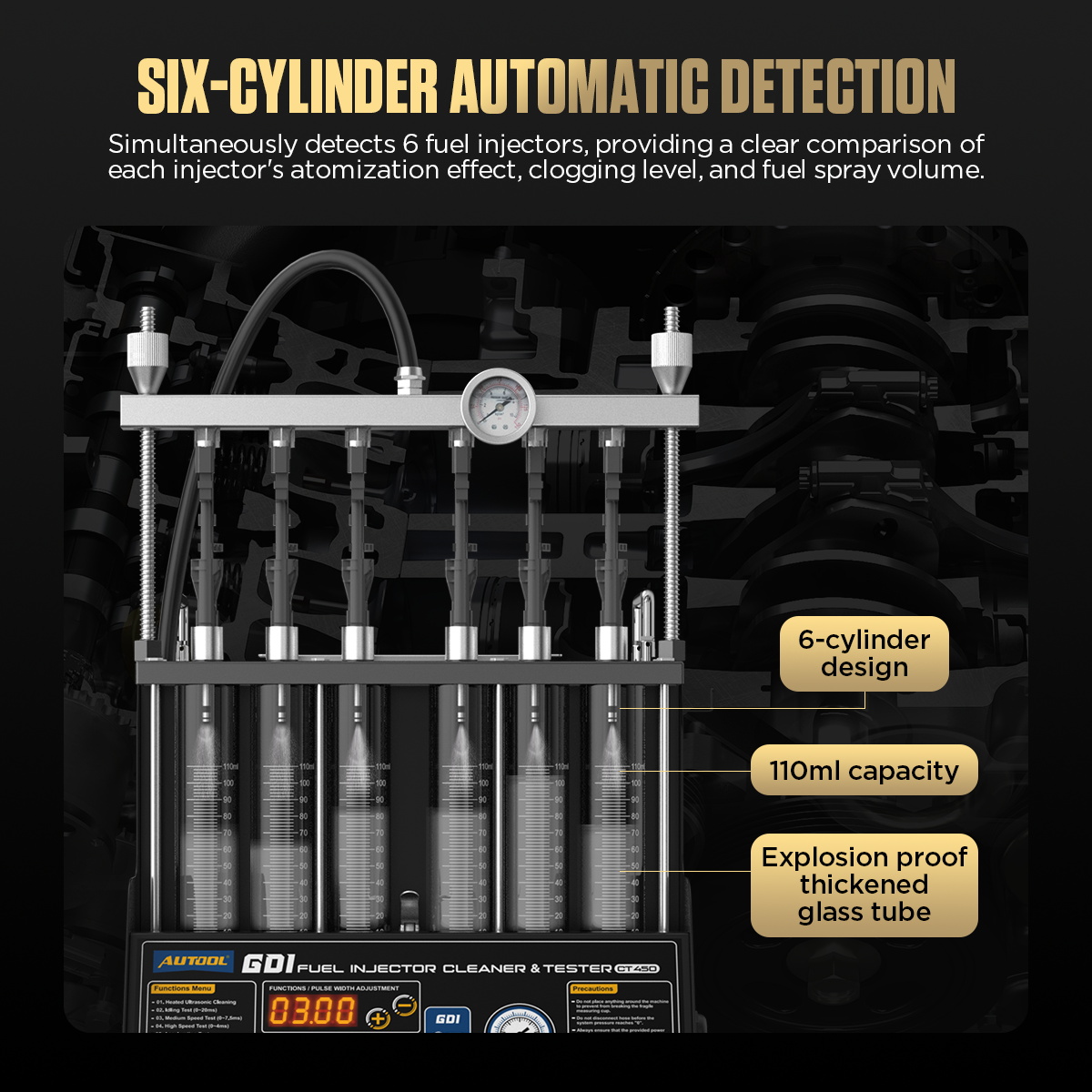

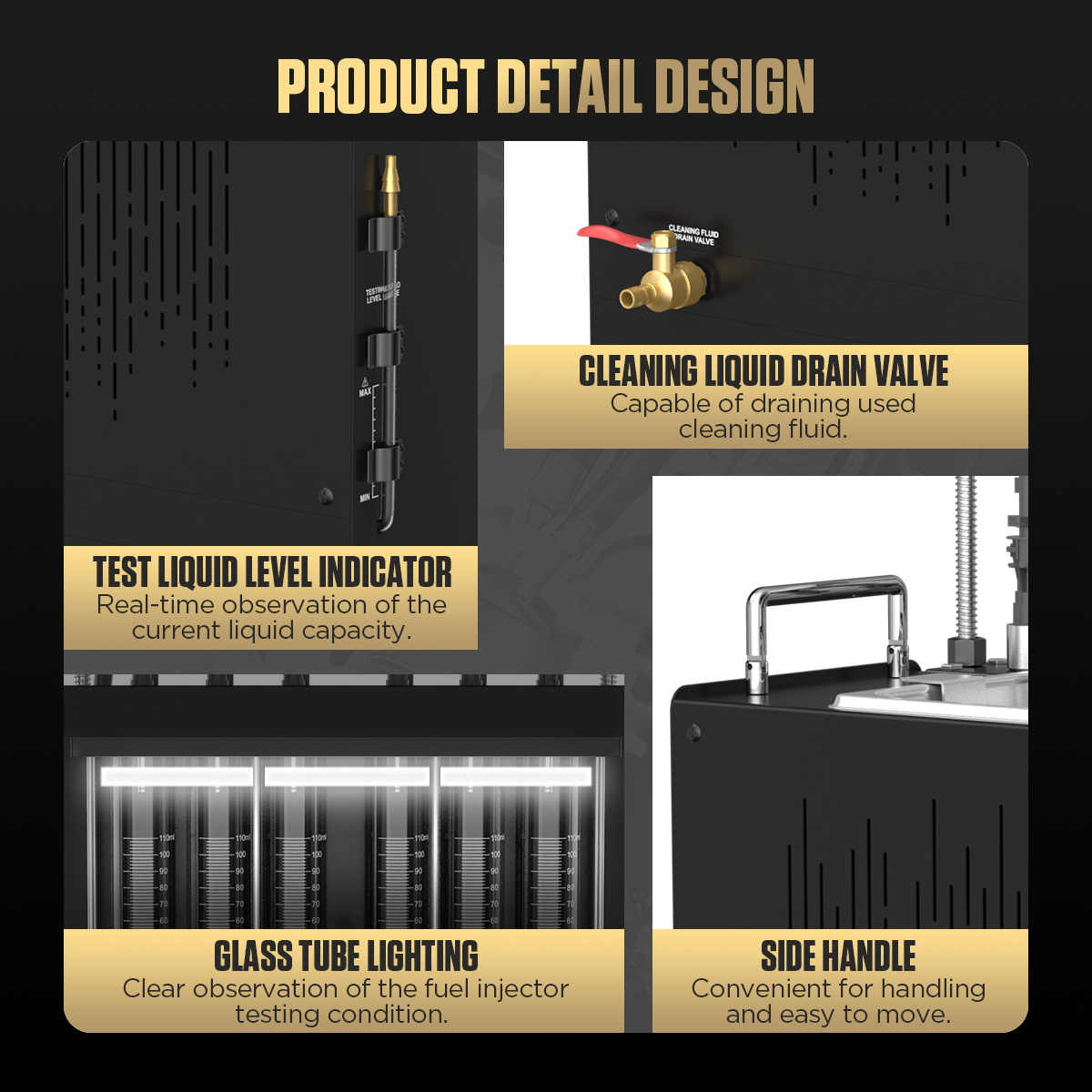

Intelligent Design: The 6-cylinder 110ml explosion-proof glass tube is designed to test up to 6 injectors simultaneously. The durable explosion-proof glass prevents fluid leakage and ensures safe and reliable operation.

Adjustable Working Time: The cleaning time of the injectors can be freely adjusted according to the dirtiness of the injectors, up to a maximum of 10 minutes.

Three-year Warranty: For damages caused by non-human factors, AUTOOL promises to provide free replacement parts within three years. If you have any requests, please feel free to contact us, and we will respond promptly within 24 hours.

AUTOOL CT450 GDI Fuel Injector Cleaner & Tester Machine Functions

Heated Ultrasonic Cleaning: Utilizes ultrasonic waves and an automatic heating system to increase cleaning efficiency, ensure thorough cleaning of injectors, and improve fuel atomization.

Reverse Flushing: Reverse flushing is a way to clean the injectors with the test liquid flowing from the outlet to the inlet of the injector. Reverse flush may remove the dirt inside the injector or the injector Strainer (Only for the top fuel supply injector).

No-disassembly Cleaning: This is Direct cleaning without disassembling the injectors. This function is an additional function that requires special adapters.

Idling Test (0-20ms): Simulate the engine idling speed and test the state of the fuel injector.

Medium Speed Test (0-7.5ms): Simulate the engine running at medium speed and test the state of the fuel injector.

High-speed Test (0-4ms): Simulate the high-speed performance of the engine and test the state of the fuel injector.

Acceleration Test: Simulate the acceleration state of the car and test the performance of the fuel injector.

Shifting Speed Test: Simulate the shifting state of the car and test the working performance of the fuel injector.

Leak Checking Test: Tests the sealing condition of the fuel injector.

Idling Spray Value Test: Simulate the engine’s idling state and test the spraying performance of the fuel injector.

Medium Speed Spray Value Test: Simulate the engine’s medium-speed state and test the spraying performance of the fuel injector.

High-speed Speed Spray Value Test: Simulate the high-speed state of the engine and test the spraying performance of the fuel injector.

Pulse Injection Test: Pulse Injection Test: Simulates various dynamic operating conditions by intermittently injecting fuel at different pulse widths and frequencies, allowing for a comprehensive assessment of the injector’s response time, atomization quality, and overall performance.