The fuel injector is a crucial component of a vehicle’s engine, responsible for atomizing high-pressure fuel and injecting it into the combustion chamber to mix with air. Over time, carbon deposits and gum formed during combustion can accumulate on the injector. If the injector is not cleaned regularly, impurities from the air and fuel may build up, leading to clogs that restrict fuel flow. This can result in decreased fuel efficiency, increased pollution emissions, and reduced engine performance.

The AUTOOL CT450 is a professional fuel injector cleaning and testing machine that combines advanced ultrasonic cleaning technology with smart microcomputer oil pressure closed-loop control technology. It features 13 cleaning and testing functions, capable of accurately simulating various engine operating conditions while performing deep cleaning and performance testing on automotive fuel injectors. The CT450 offers three selectable working voltages: 12V, 70V, and 120V, making it compatible with GDI, EFI, FSI, and other types of injectors. It meets the cleaning and testing requirements for GDI injectors across core automotive brands such as Mercedes-Benz, BMW, Audi, Porsche, and Ford. The equipment also features intelligent injector drive voltage recognition. If the wrong voltage is selected, it will immediately issue an alert to prevent damage to the injector due to incorrect voltage selection. In addition, the CT450 is equipped with a smart constant temperature heating function that automatically heats the cleaning fluid to the optimal working temperature (50°C) during the cleaning process, enhancing the activity of the cleaning solution and resulting in a more thorough cleaning effect.

Main Features and Characteristics:

Ultrasonic Cleaning Technology

The AUTOOL CT450 adopts ultrasonic cleaning technology with powerful cleaning strength. It utilizes high-frequency vibrations to generate a cavitation effect in the liquid, thoroughly removing stubborn impurities from the gaps in the injector while ensuring no wear to the injector’s surface.

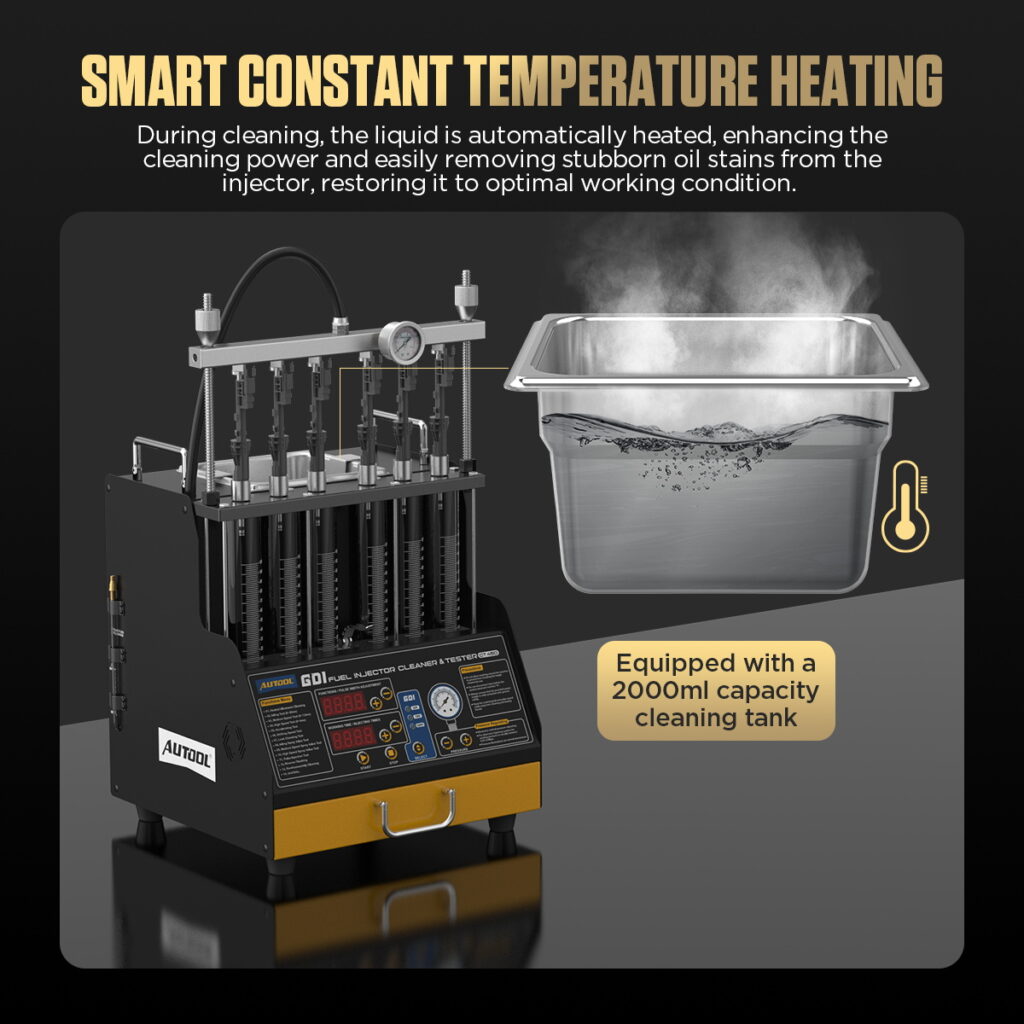

Smart Constant Temperature Heating

The AUTOOL CT450 is equipped with an intelligent constant temperature heating function, which automatically heats the cleaning fluid to the optimal working temperature (50°C) during the cleaning process, effectively enhancing the activity of the cleaning solution and more effectively removing stubborn impurities from the fuel injector.

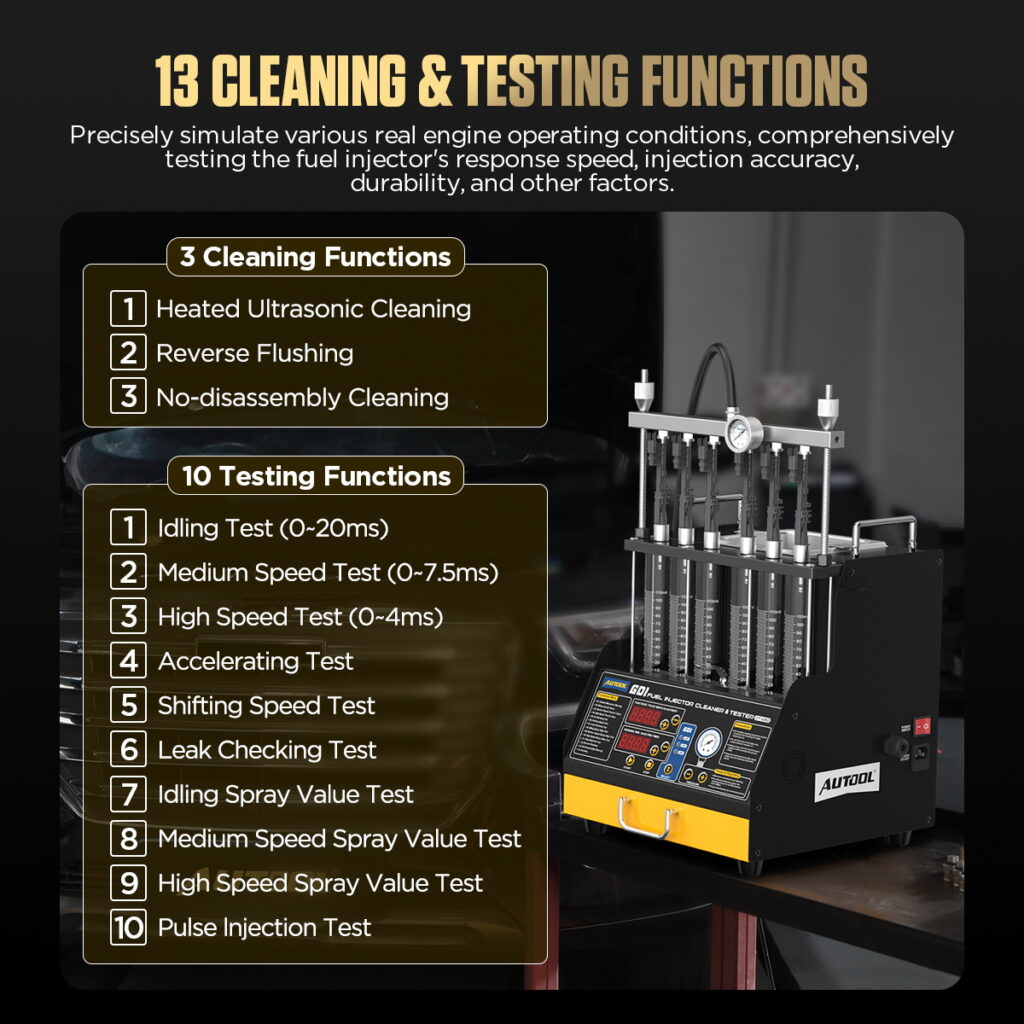

13 Cleaning & Testing Functions

1. Ultrasonic Cleaning: By sending signals to the fuel injectors via the pulse adapter cable, ultrasonic waves are used to thoroughly remove carbon deposits and impurities from the injectors.

2. Reverse Flushing: Using reverse flushing, the cleaning fluid is injected through the fuel injection port and flows out through the fuel inlet, thoroughly cleaning the internal carbon deposits of the injectors.

3. Non-Disassembly Cleaning: Connect specialized components to clean the combustion chamber or throttle body without removing the injectors.

4. Idle Speed Test (0-20ms): Simulate engine idle speed operation to test injector performance.

5. Medium Speed Test (0-7.5ms): Simulate stable engine running conditions to test injector performance.

6. High Speed Test (0-4ms): Simulate high-speed engine operation to test injector performance.

7. Acceleration Test: Simulate the engine’s state from static to acceleration to test injector performance.

8. Variable Speed Test: Simulate the vehicle’s gear shifting state to test injector performance.

9. Leakage Test: Simulate the dynamic liquid pressure inside the container during engine operation to test injector performance.

10. Idle Injection Volume Test: Simulate the engine’s idle state to test the atomization performance of the injector.

11. Medium-Speed Injection Volume Test: Simulate the engine’s mid-speed state to test the atomization performance of the injector.

12. High-Speed Injection Volume Test: Simulate the engine’s high-speed state to test the atomization performance of the injector.

13. Pulse Injection Test: Simulate the engine’s idle speed and load conditions to test injector performance.

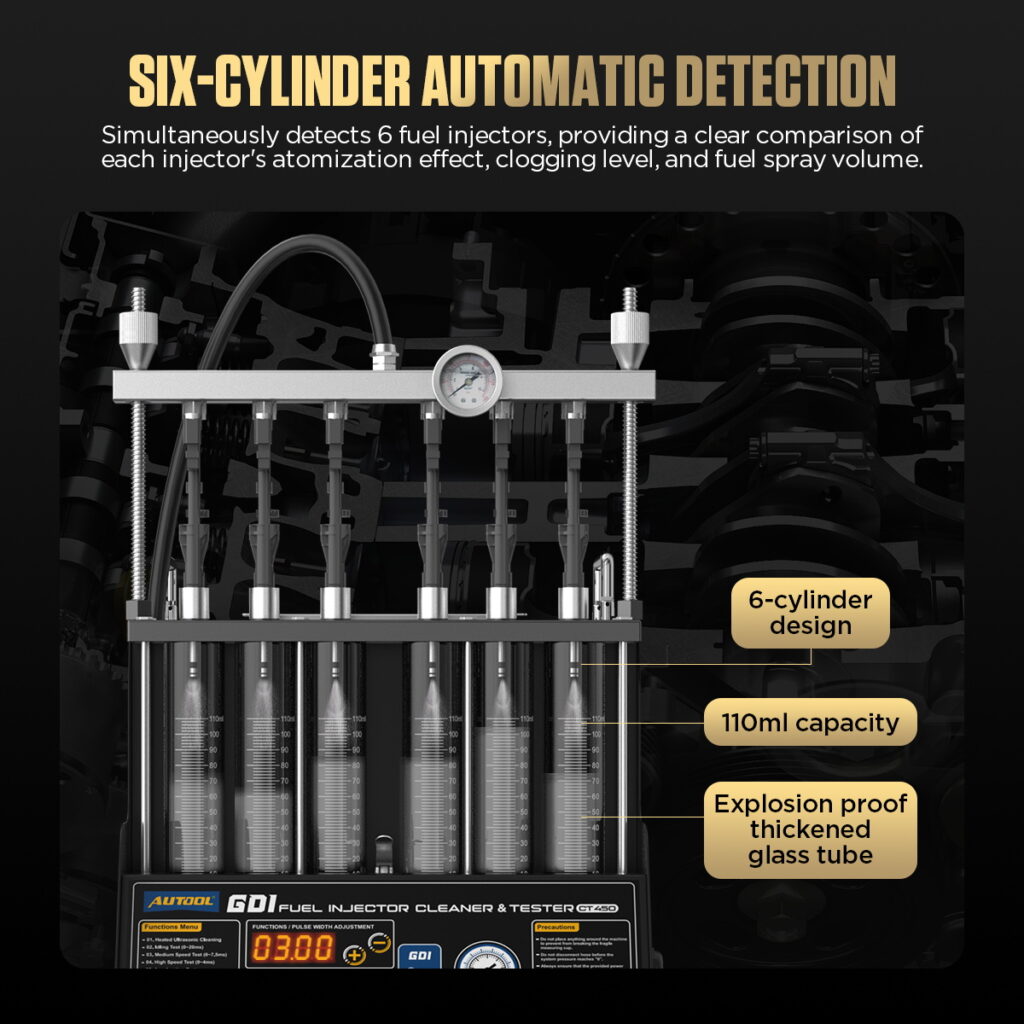

Six-cylinder Automatic Detection

The AUTOOL CT450 is equipped with 6 test tubes of 110ml, allowing for simultaneous testing of multiple fuel injectors. It simulates operating conditions to provide a clear comparison of changes in injector nozzle size, clogging, and leakage, offering a comprehensive evaluation of the injectors’ performance.

Compatible with Various Fuel Injectors

The AUTOOL CT450 is equipped with 9 different composite adapter specifications, supporting three voltage options: 12V, 70V, and 120V. It is fully compatible with the cleaning and testing requirements of GDI, EFI, FSI, and conventional fuel injectors. Additionally, it features intelligent voltage recognition for injector drive and will automatically alert if the selected voltage is mismatched.

Smart Control Panel

The AUTOOL CT450 features a HD backlit digital screen and graphical function buttons for clear data display and intuitive operation. Within the specified parameter range, users can flexibly adjust test pressure, test duration, and pulse width.

Bottom Drawer Design

The AUTOOL CT450 features a built-in parts drawer at the bottom, which does not require extra storage management and can store various connector accessories according to their labels.

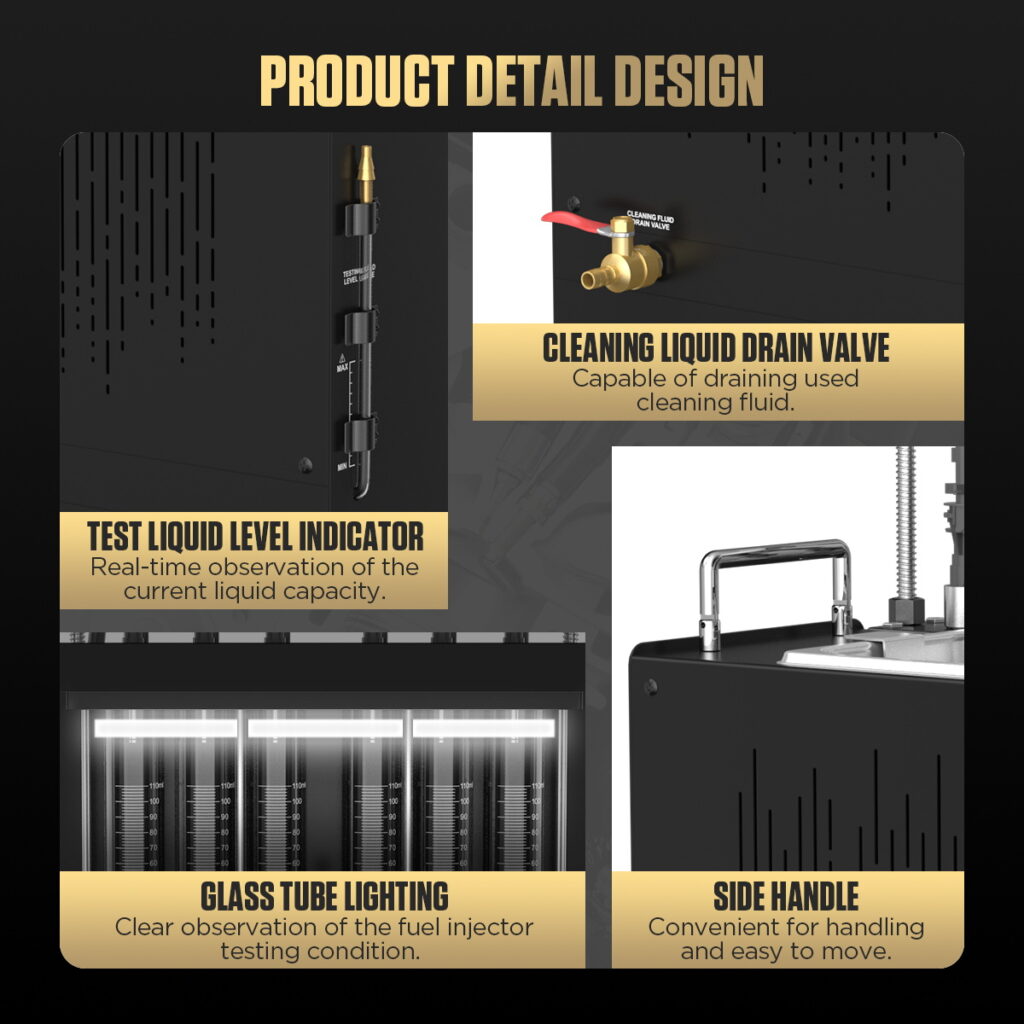

Product Detail Design

Cleaning liquid drain valve: Recycles used cleaning fluid in a timely manner, followed by cleaning and maintenance of the cleaning tank.

Test fluid level gauge: Monitors the real-time test fluid level, allowing timely replenishment when low.

Glass tube lighting: Ensures clear visibility of the injector test status, even in dim environments.

Side handle design: Enhances portability, making movement more convenient and comfortable.

AUTOOL CT450 is a multifunctional equipment designed for the automotive repair industry and cleaning components. Independently developed by AUTOOL, it has a number of intellectual property rights, as well as the authoritative certification of CE, FCC, ROHS and other testing organizations. The appearance adopts an HD backlit digital screen and a multifunctional panel, ensuring clear data display and intuitive, user-friendly operation. It features a built-in 2000ml large-capacity cleaning tank, allowing simultaneous cleaning and testing of multiple fuel injectors to improve work efficiency. Additionally, it accurately simulates the operating status of the engine under various working conditions such as idle, medium, and high speed. Whether for routine maintenance or troubleshooting, the CT450 delivers comprehensive and efficient support for fuel injector servicing.