AUTOOL LM708 1234yf Fefrigerant Working Principle

Vacuuming: Utilizes a vacuum pump to remove air and moisture from the refrigeration system, ensuring no impurities affect the refrigerant flling process.

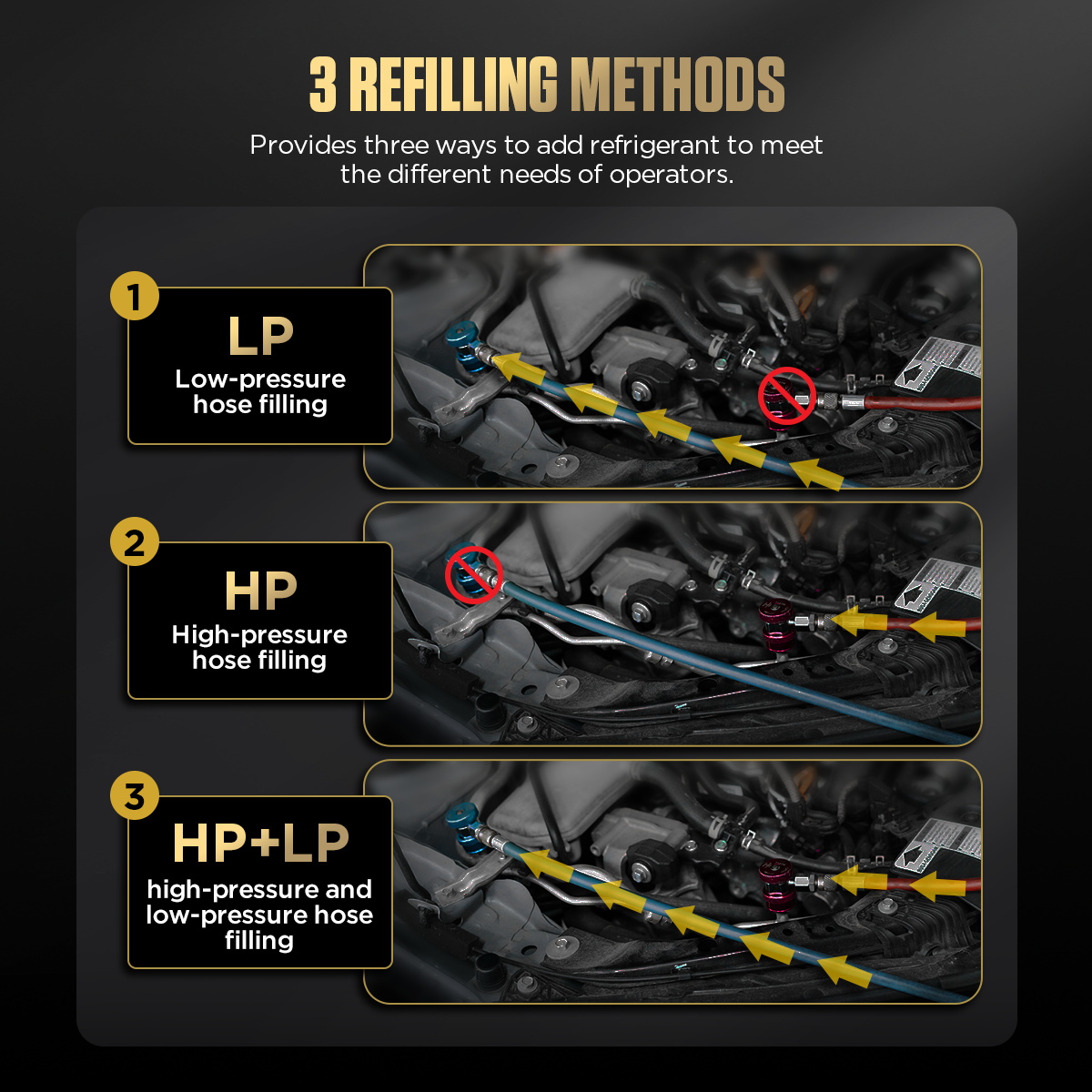

Refrigerant Filling: Uses a flow control valve and pressure sensor to precisely transfer refrigerant from the storage tank into the refrigeration system, completing the filling process according to the preset amount.

Smart Monitoring: Real-time monitoring of pressure and flow to prevent overfilling or insufficient filling. Automatic shutoff and alert for abnormal conditions.

Safety Protection: Continuous monitoring of temperature and pressure to prevent refrigerant leakage or overpressure, ensuring the safety of the equipment and operators.

The core lies in vacuuming, precise filling, and intelligent control, achieving an efficient, safe, and environmentally friendly refrigerant filling process.

AUTOOL LM708 refrigerant identifier Features

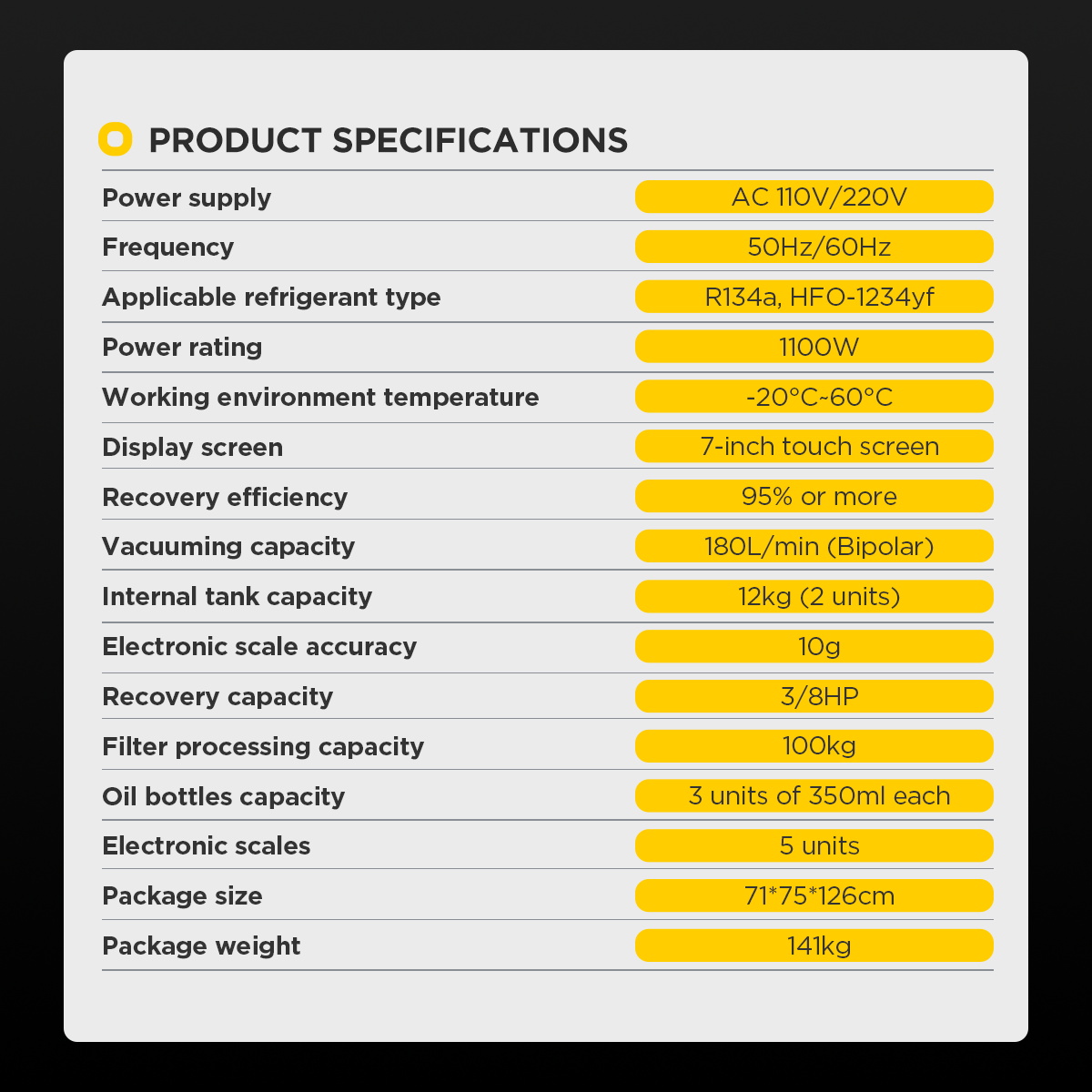

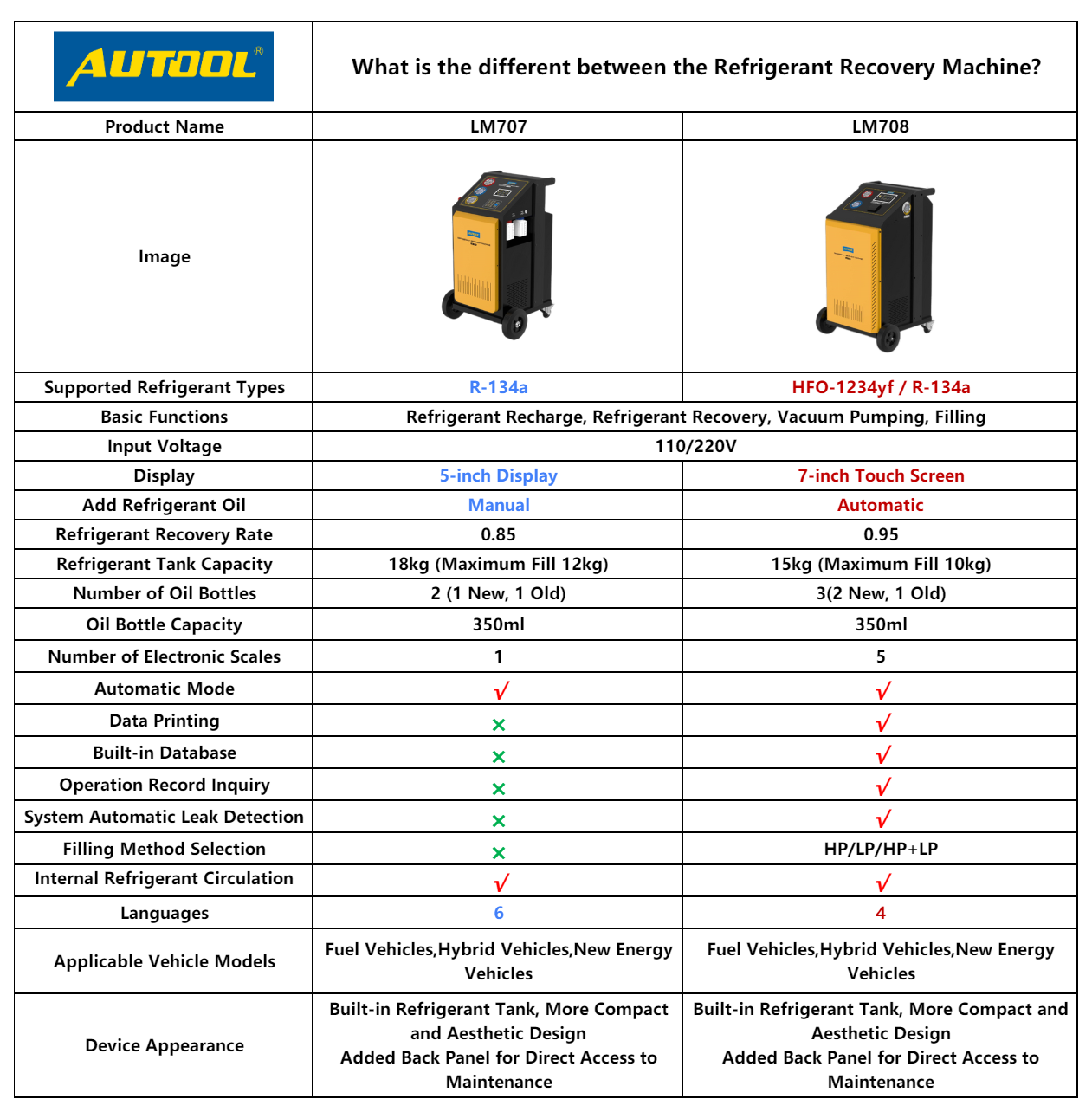

Fully Automatic and Manual: The R134 and 1234yf dual refrigerant recovery and filling machine. The AUTOOL LM708 refrigerant recovery machine integrates refrigerant recovery, vacuum pumping, filling, refrigerant oil injection, automatic operation, AC pressure testing, leak detection, and more into a single unit.

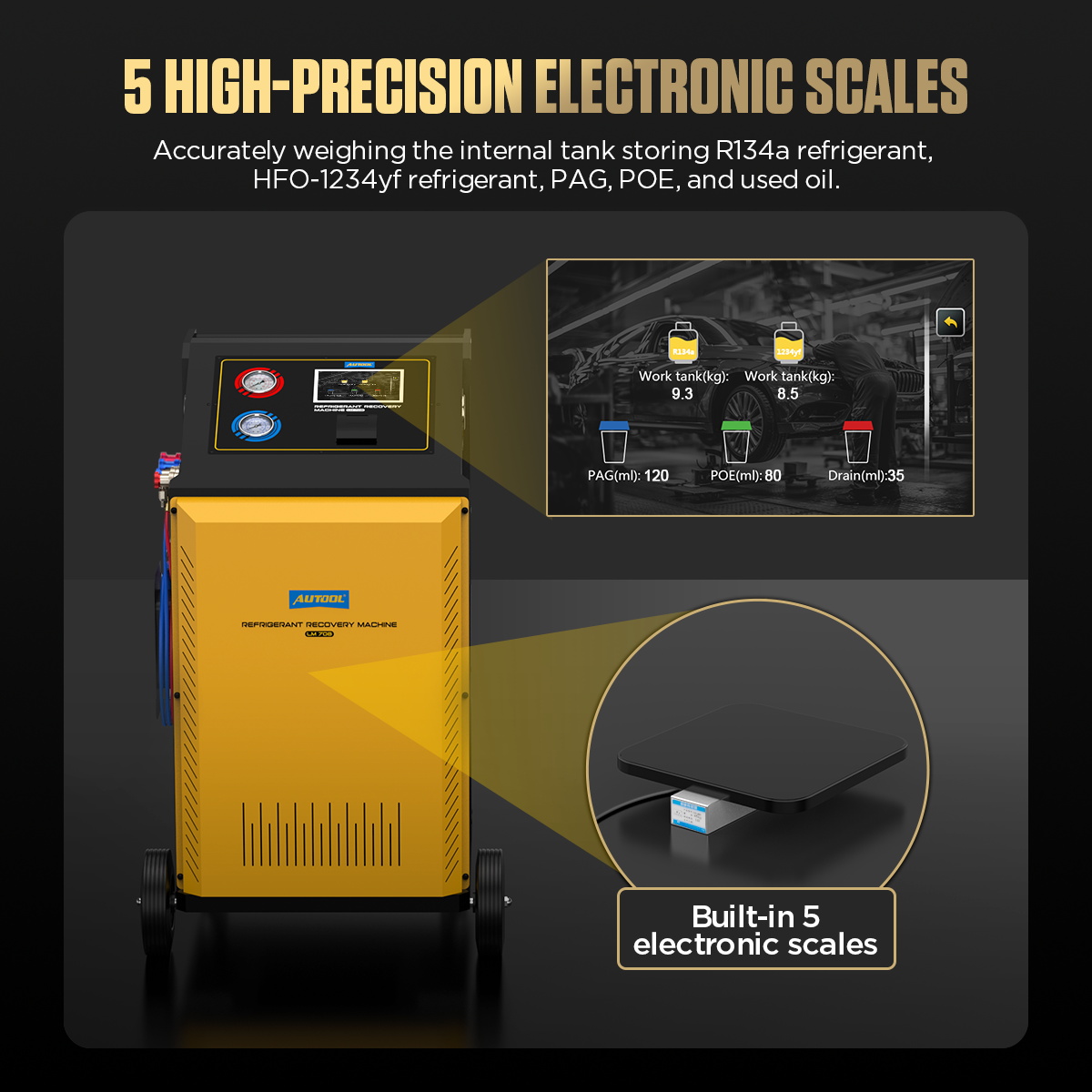

5 Electronic Scales: Equipped with 5 high-precision electronic scales, the machine can accurately weigh the R134a tank, 1234yf tank, PAG oil tank, POE oil tank, and waste oil tank. This enables automatic and precise refrigerant oil injection.

Fully Automatic Operation and Smart Control Panel: After setting the relevant parameters, the machine will operate fully automatically. The refrigerant recovery machine is equipped with a 7-inch LCD touchscreen that provides step-by-step operation prompts.

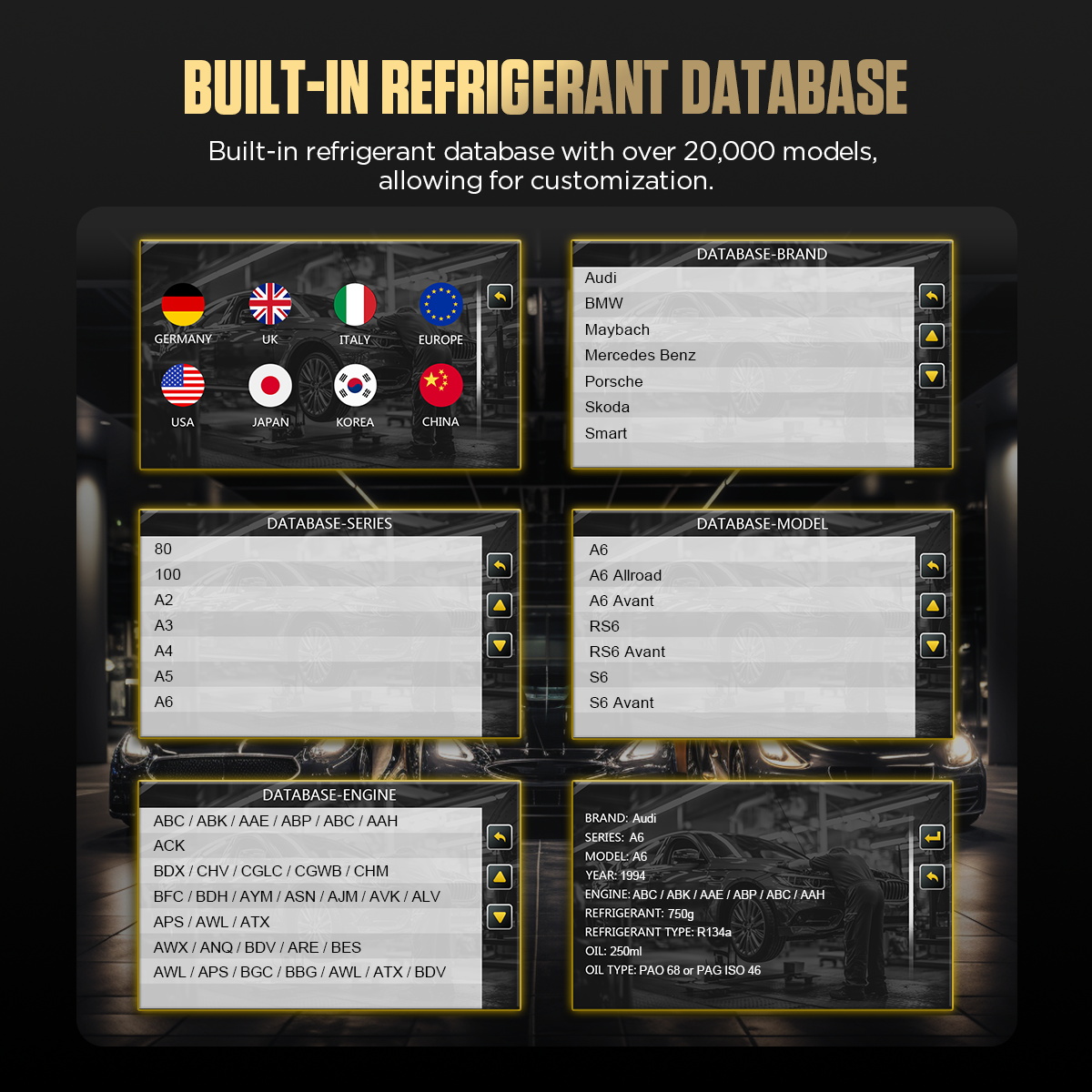

Powerful Data Support: This refrigerant recovery machine is equipped with a database of over 20,000 vehicle models. It features a data query function, allowing you to access the machine’s operation records at any time. An integrated printer can also print the required operation records.

Recovery, Purification, and Reuse: The upgraded deep recovery function purifies the refrigerant during the recovery process, enabling the refrigerant to be regenerated and reused. The recovery efficiency has been increased to over 95%. The equipment includes an automatic internal pipeline cleaning operation to prevent the mixing of different refrigerants and compressor oils.

AUTOOL LM708 Automotive Refrigerant Operating Instructions

Preparation: Inspect the equipment, select the appropriate refrigerant, and prepare the necessary tools.

Connect the Pipelines: Connect the machine to the refrigeration system, ensuring there are no leaks.

Vacuum Pumping: Start the vacuum pump to remove air and moisture from the system.

Refrigerant Filling: Set the filling amount, start the machine to accurately inject refrigerant, and monitor the pressure and flow.

Inspection and Testing: Ensure the system pressure is normal and test the cooling effect.

Turn Off the Equipment: After filling is complete, turn off the equipment and disconnect the hoses.

Cleaning: Check for leaks, clean the tools, and properly dispose of the used refrigerant.