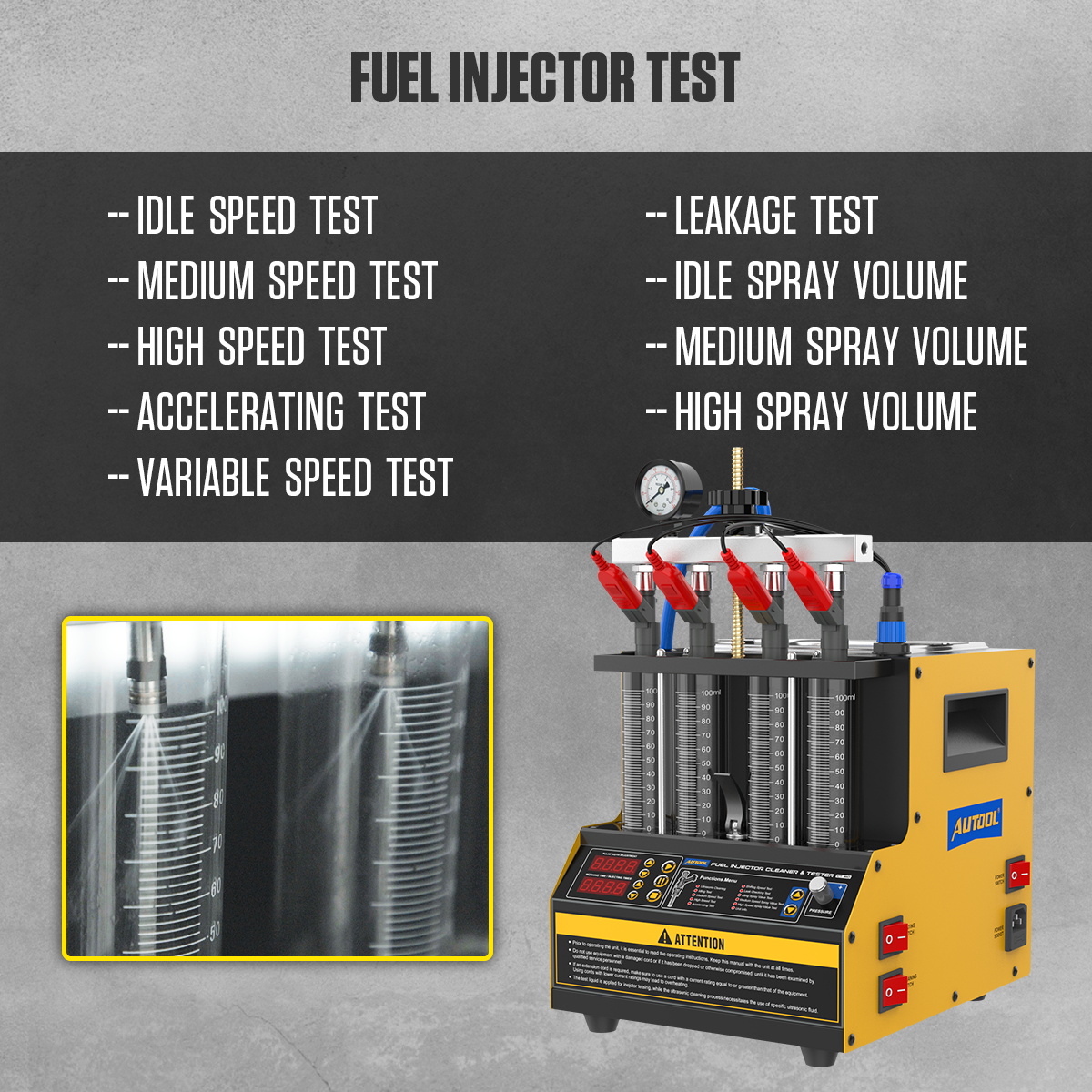

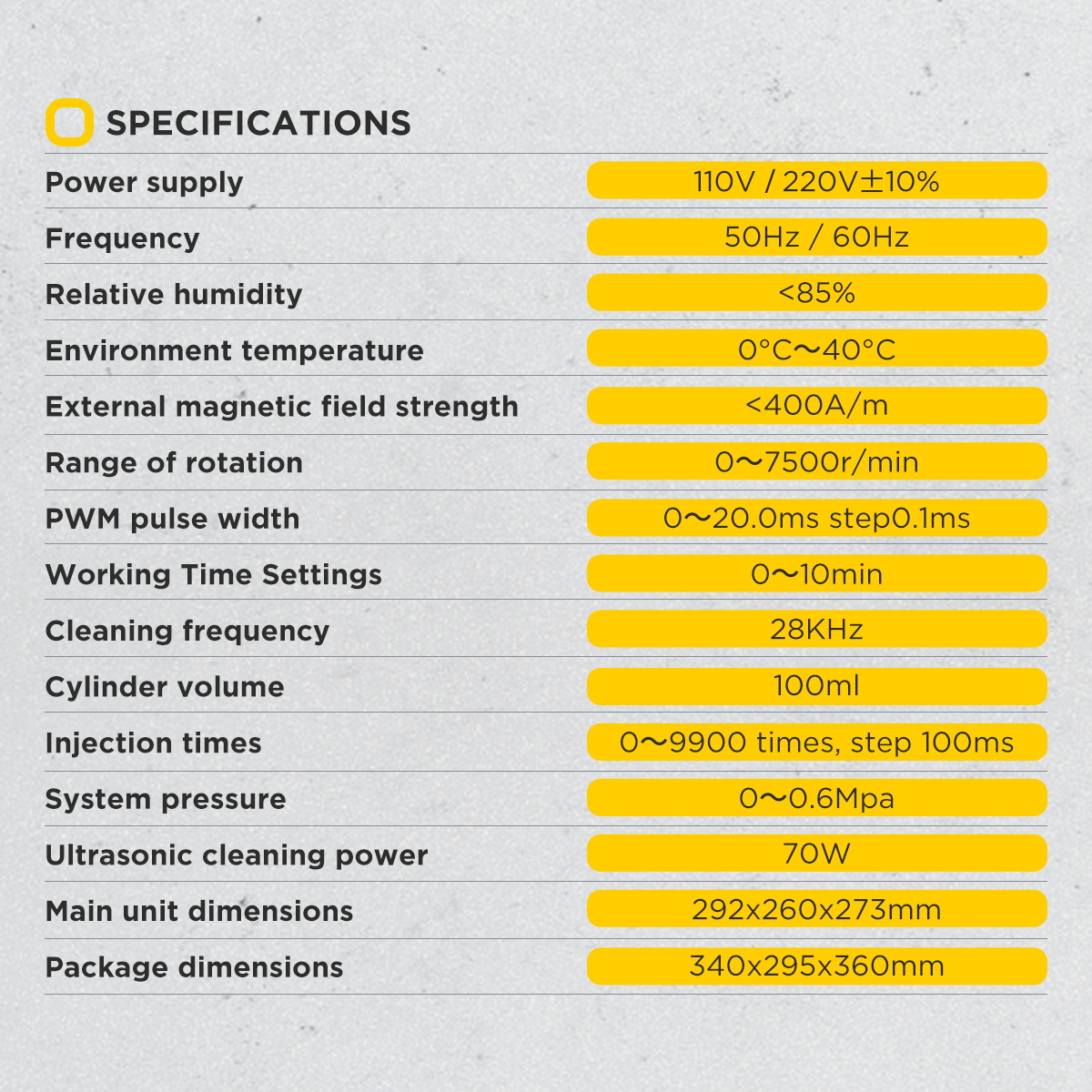

Idle Speed Test (0-20ms): Simulates engine idle speed operation to test the performance of the fuel injectors.

Medium-Speed Test (0-7.5ms): Simulates engine mid-speed operation to test the fuel injector performance.

High-Speed Test (0-4ms): Simulates engine high-speed operation to test the performance of the fuel injectors.

Acceleration Test: Simulates vehicle’s acceleration state to test the working performance of the fuel injectors.

Shift Speed Test: Simulates the vehicle’s gear-shifting state to test the working performance of the fuel injectors.

Leakage Check Test: Tests the sealing integrity of the fuel injectors.

Idle Spray Test: Simulates the engine’s idle state to test the injector’s spray performance.

Mid-Speed Spray Test: Simulates the engine’s mid-speed state to test the injector’s spray performance.

High-Speed Spray Test: Simulates the engine’s high-speed state to test the injector’s spray performance.

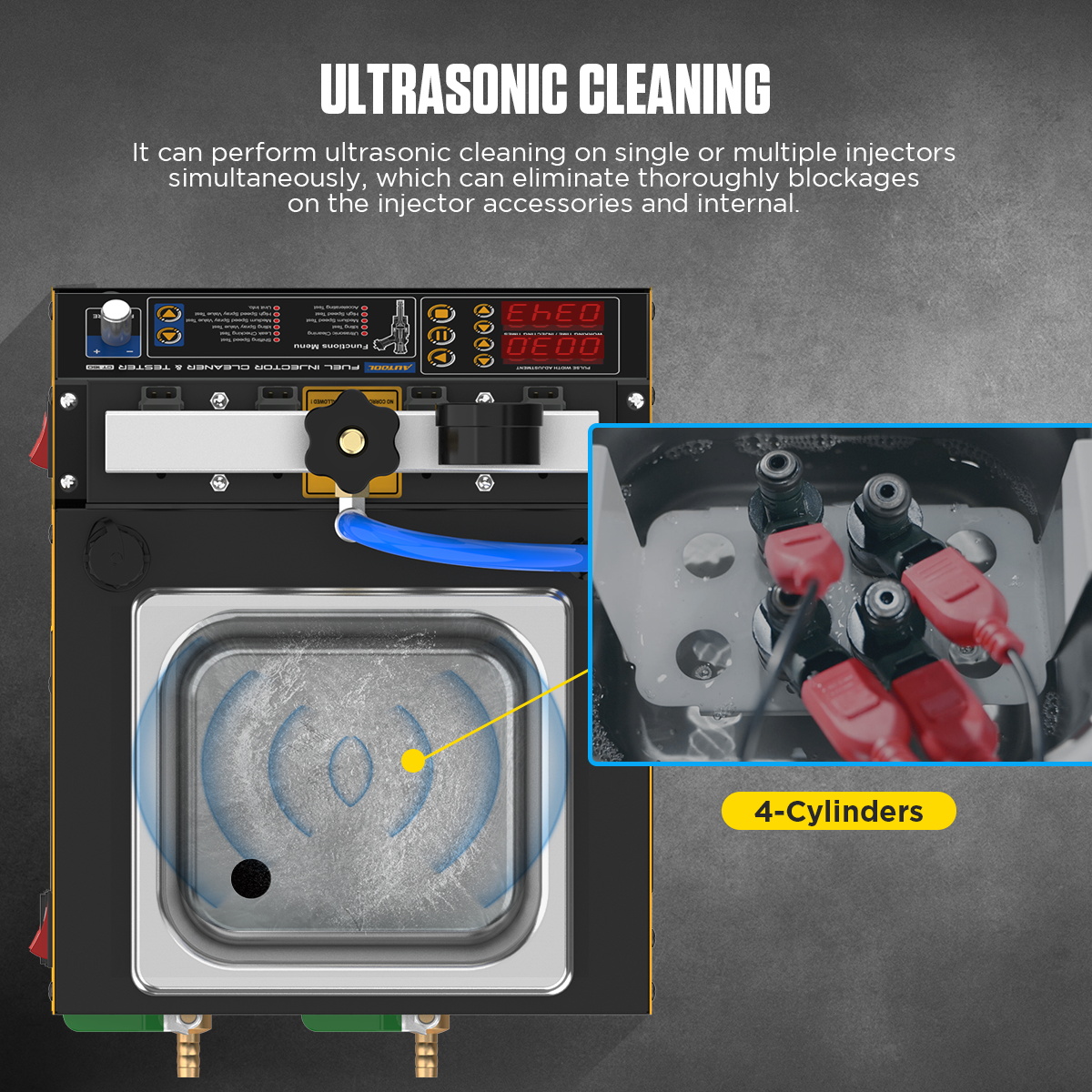

Ultrasonic Deep Cleaning: The CT160 Fuel Injector Tester & Cleaner utilizes pulse signal cables to send signals to the fuel injectors, combined with cleaning fluid and ultrasonic vibration technology. This process efficiently removes carbon deposits and stubborn impurities inside the fuel injectors, ensuring thorough and deep cleaning.

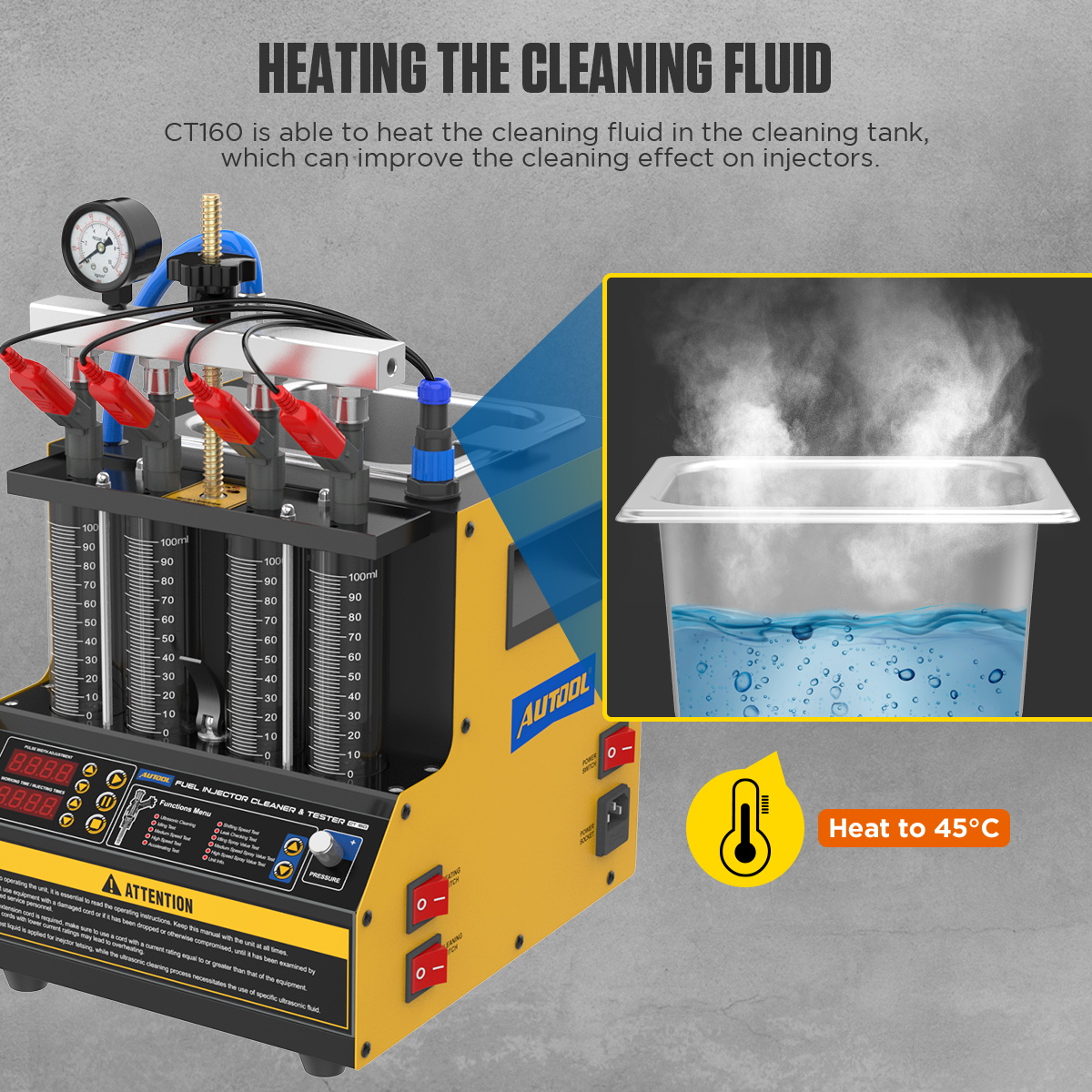

Cleaning Fluid Heating Function: Equipped with a unique heating function, it can heat the cleaning fluid to 40°C, significantly enhancing cleaning effectiveness and thoroughly removing stubborn dirt from the injectors and accessories, ensuring a more efficient cleaning process.

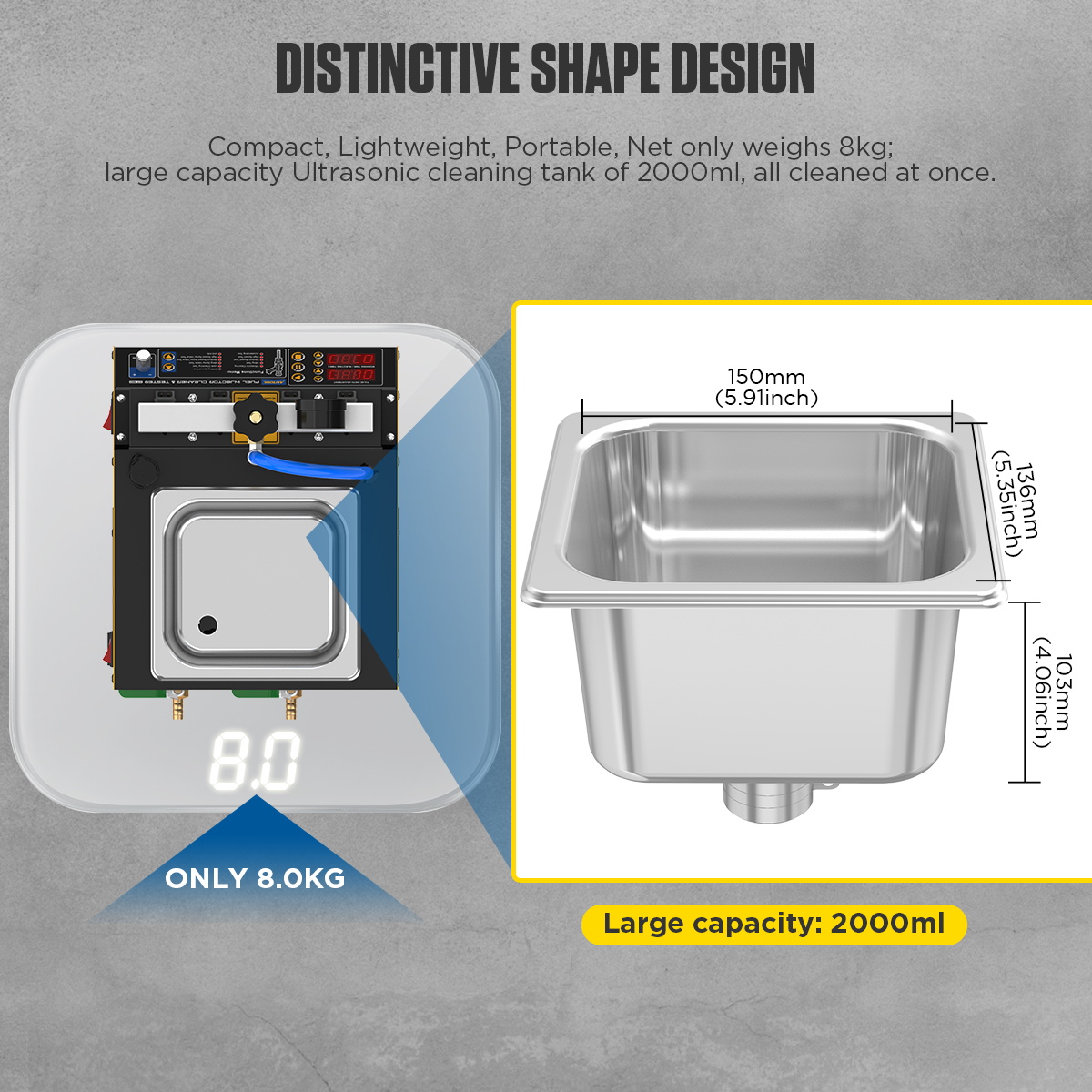

Large Capacity Cleaning Tank: Equipped with an ultrasonic cleaning tank measuring 150x136x103(mm) and a 2000ml capacity, it is not only suitable for cleaning automotive fuel injectors but also capable of cleaning other automotive components.

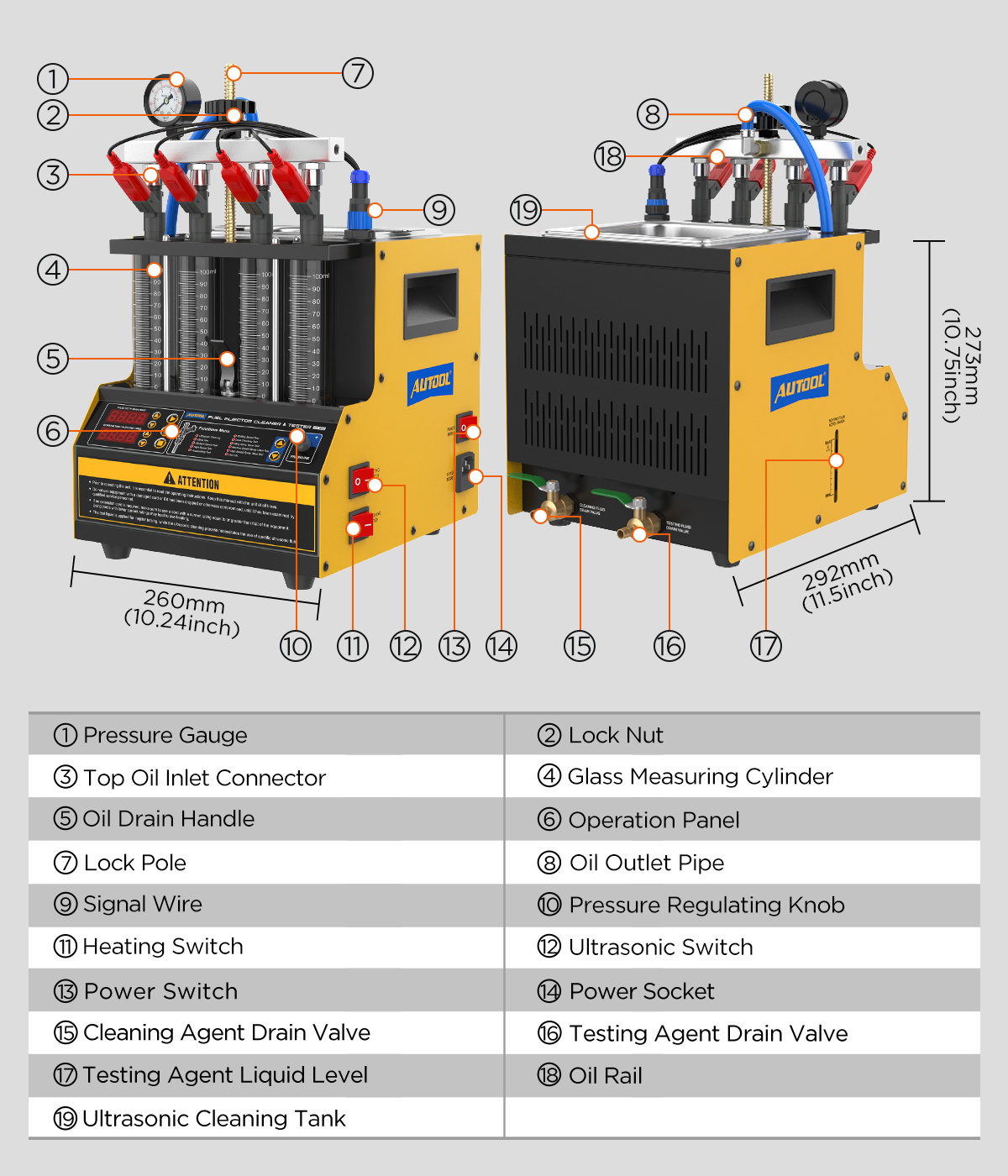

Multi-Injector Cleaning and Testing: The CT160 Fuel Injector Tester & Cleaner features four independent glass tubes, enabling the simultaneous cleaning and testing of up to four injectors. This greatly enhances cleaning efficiency, streamlines the testing process, and ensures more convenient operation.

Stable and Reliable Pressure: The equipment uses advanced electronic pressure regulation technology to ensure stable and precise fuel pressure at all times. It is equipped with a high-quality fuel pump, ensuring reliable performance and supporting long-term stable operation of the equipment.

Intuitive Display Function: Equipped with a liquid level gauge for precise indication of the added test fluid volume, ensuring accurate test results. The pressure gauge provides real-time monitoring of test pressure, effectively preventing excessive pressure from damaging the equipment or injectors, ensuring safer and more reliable operation.

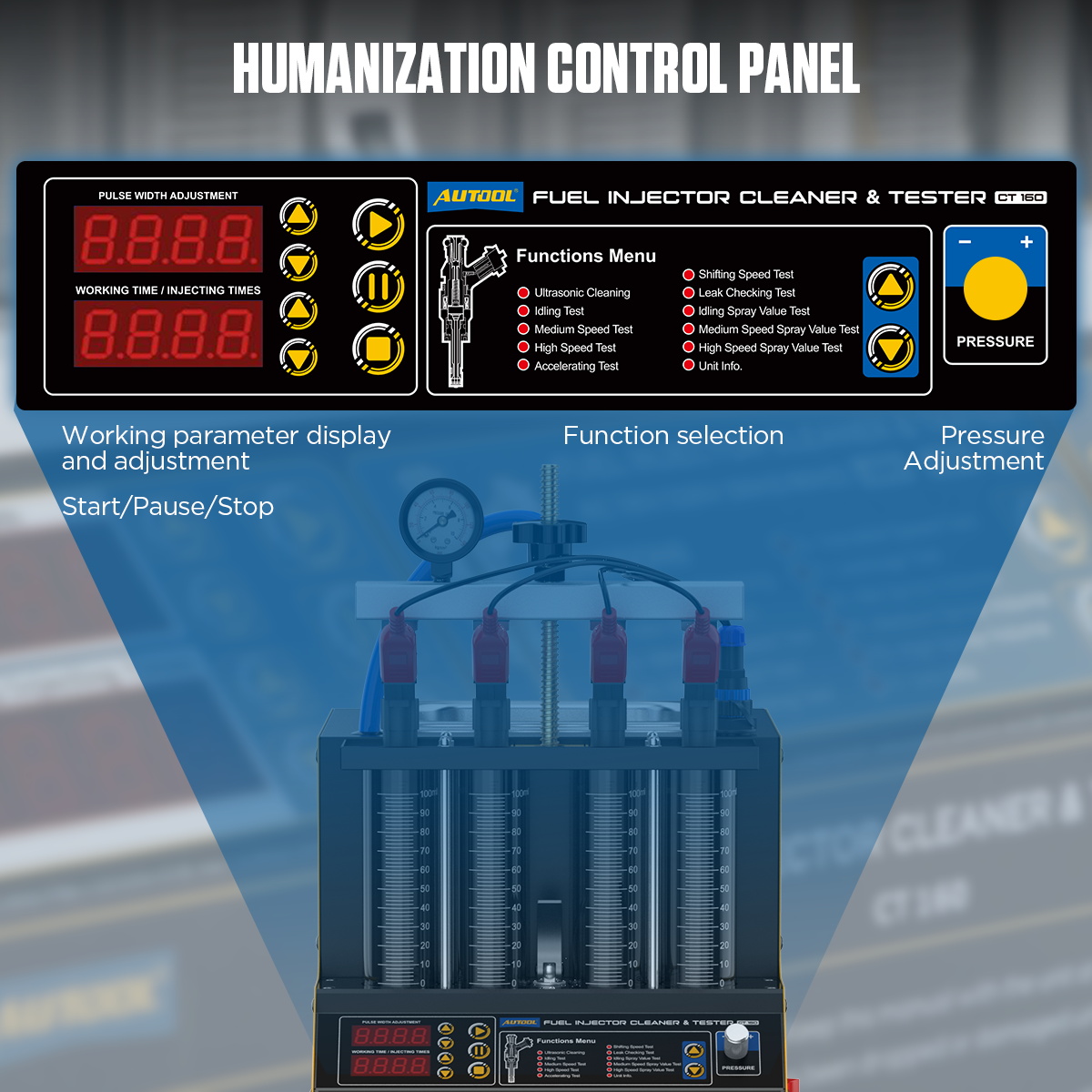

Flexible Operation: Supports freely adjusting the injector’s test time, working frequency, spray count, and shortest switching cycle within the adjustable range, easily adapting to various cleaning and testing requirements to meet different work demands.

Wide Application: Equipped with interchangeable composite connectors suitable for various vehicle models, supporting the testing and cleaning of nearly all gasoline vehicle injectors available on the market.

Operating Instructions

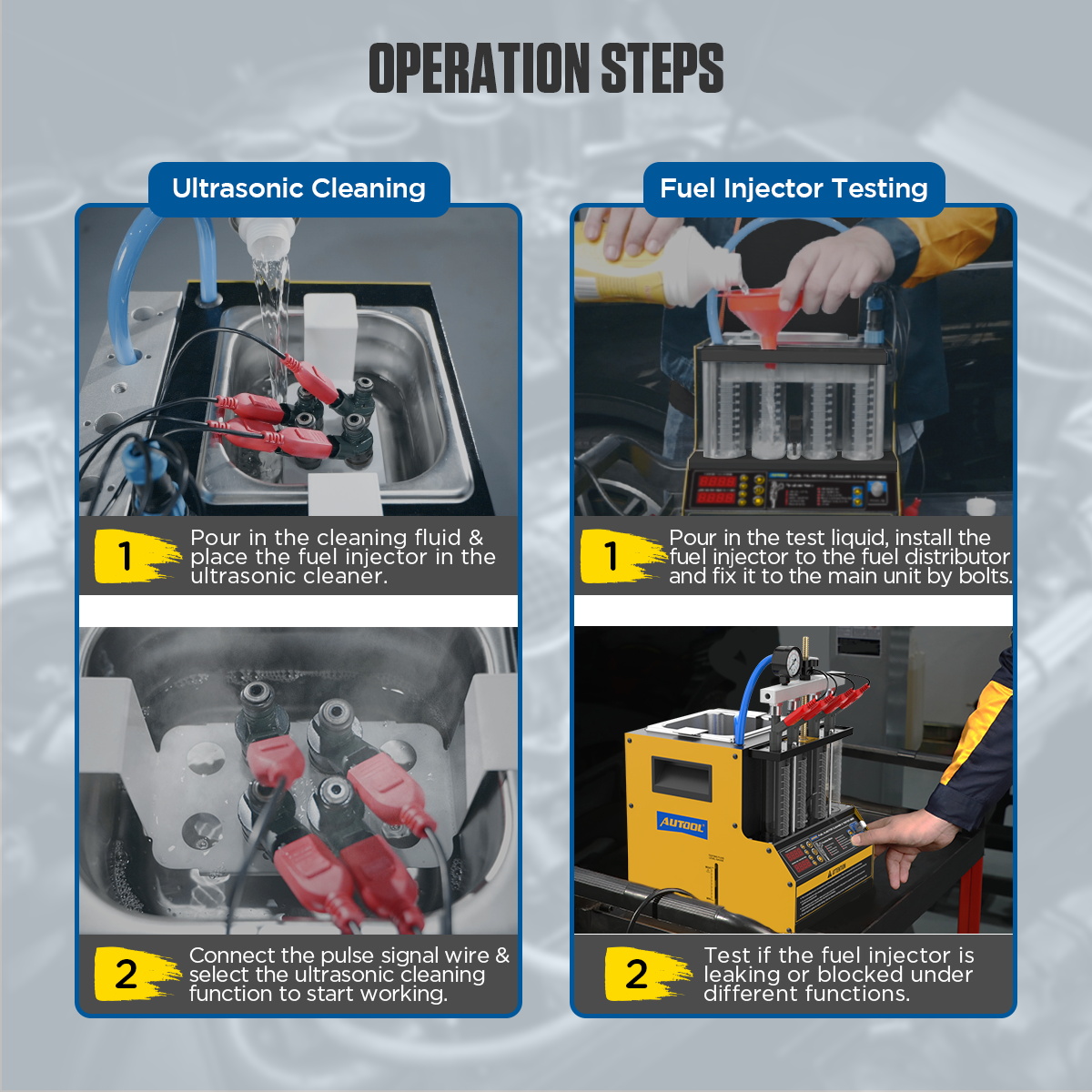

Ultrasonic Cleaning:

Clean the exterior of the injectors with cleaning solution before turning on the machine.

Once the exterior of the injectors is free of dirt, place the injectors into the ultrasonic cleaning tank.

Add cleaning solution, ensuring it does not exceed the connection port of the pulse pipeline.

Connect the pulse signal line and select the first ultrasonic cleaning function to start.

Allow the ultrasonic cleaning function to run for deep cleaning.

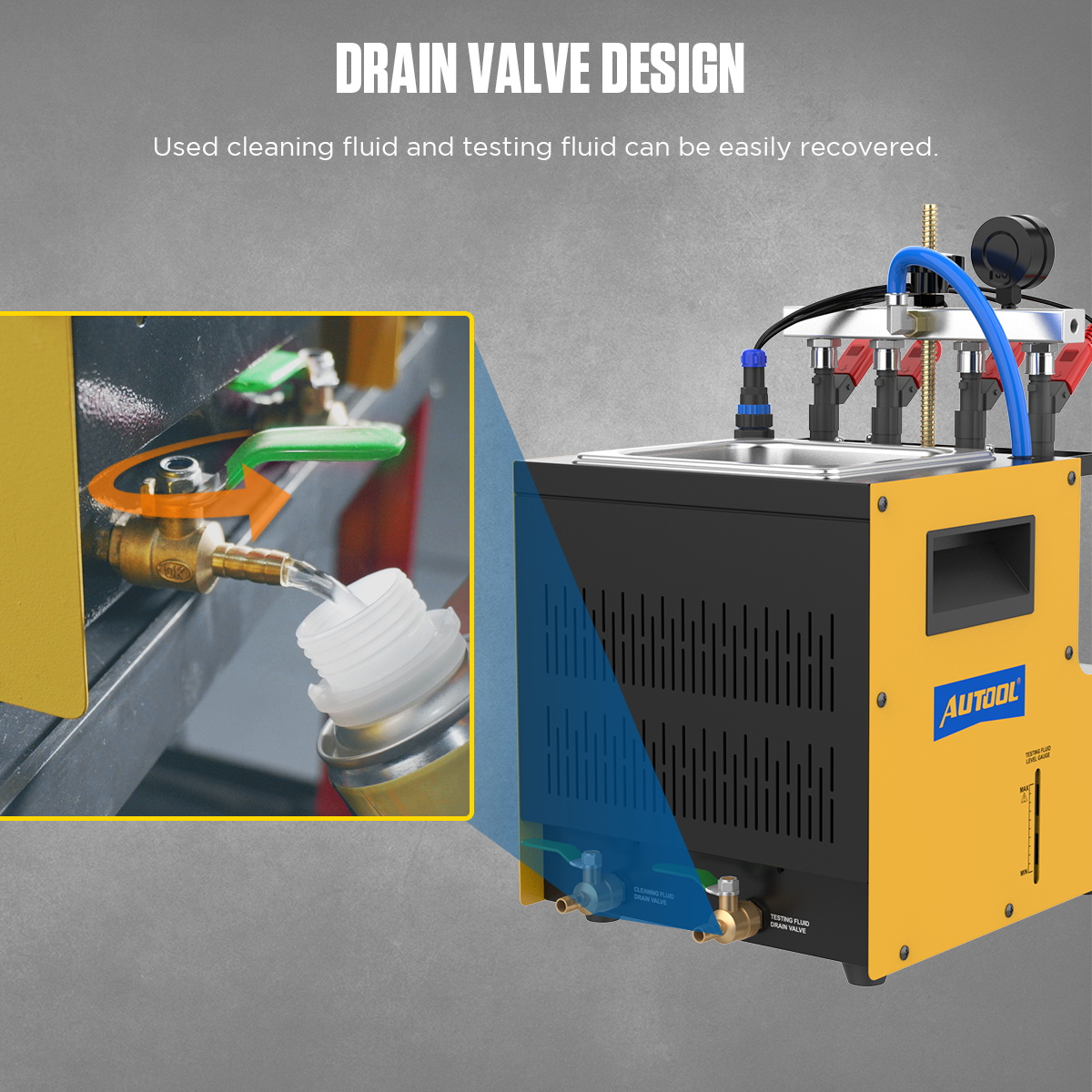

After cleaning, recover the remaining cleaning solution.

Fuel Injector Testing:

Secure the injector onto the main unit, and test the injector’s resistance, short circuit, and current.

Fill half of the glass tube with the testing solution.

Perform leakage, spray mode, and flow rate tests on the flow bench.

Finally, place the injector back on the flow bench and retest all functions.

Tips:

Use professional engine carbon cleaning fluid as the ultrasonic cleaning fluid to ensure optimal cleaning results and equipment safety.

When performing injector tests, select professional testing fluid and avoid corrosive liquids; anhydrous alcohol is recommended.

After use, promptly drain all liquids from the equipment and clean it properly to extend the machine’s lifespan.