BT250 Automotive Circuit Tester

The AUTOOL BT250 is a tool designed for automotive electrical circuit maintenance and testing. It features a high-definition color display and offers four testing modes, allowing you to easily switch between DC voltage testing, AC voltage testing, resistance testing, and diode testing. Additionally, it has been updated to display key data such as AC voltage frequency, duty cycle, and more, enabling you to quickly trace and identify faults and faulty circuits in the automotive electrical system. It is an efficient and advanced circuit tester.

Working Principle

The AUTOOL BT250 Electrical System Tester uses electromagnetic induction to check voltage signals. When the device’s metal probe contacts a circuit, its built-in highly sensitive sensing component detects the alternating magnetic field around the circuit. If current is flowing through the circuit, the LED indicator on the device immediately lights up, providing you with an intuitive and accurate display of the electrode’s properties.

Features

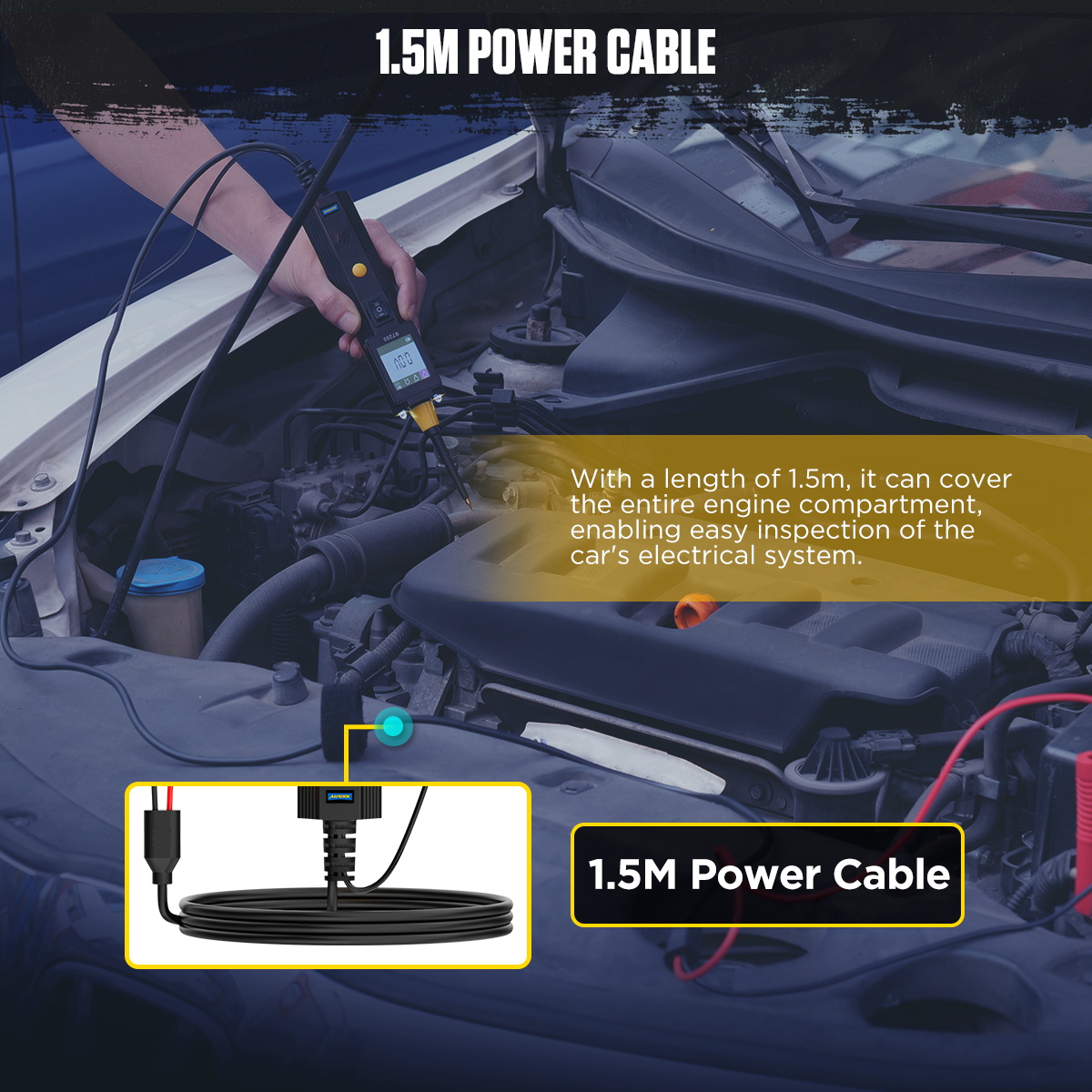

Professional Circuit Tester: Powered by the car’s battery or cigarette lighter, no additional batteries or cables are required. In addition to testing circuits related to components, it can also serve as a temporary power source for testing vehicle components like radiator fans, starter motors, relays, window regulators, and windshield wipers.

Wide Vehicle Compatibility: Voltage test range of 0-65V, supports testing for various types of vehicles, including cars, motorcycles, trucks, excavators, ships, RVs, and more.

Multiple Application Functions: The circuit tester features four testing modes, allowing for flexible switching between DC voltage testing, AC voltage testing, resistance testing, and diode testing. It supports polarity identification, continuity testing, signal circuit testing, ground fault testing, circuit tracing and locating, jumper wire detection, and activation of components.

Easily Locate Faults: The BT250 allows you to easily identify issues such as circuit breaks, open or closed circuits, and short circuits. It helps test vehicle switches, relays, headlights, taillights, faulty sockets, diodes, fuses, wires, and the continuity of electrical circuits.

Automatic Short Circuit Protection: The circuit finder comes with short circuit protection. If an overload or short circuit occurs, the device will automatically restart to protect both the device and the vehicle.

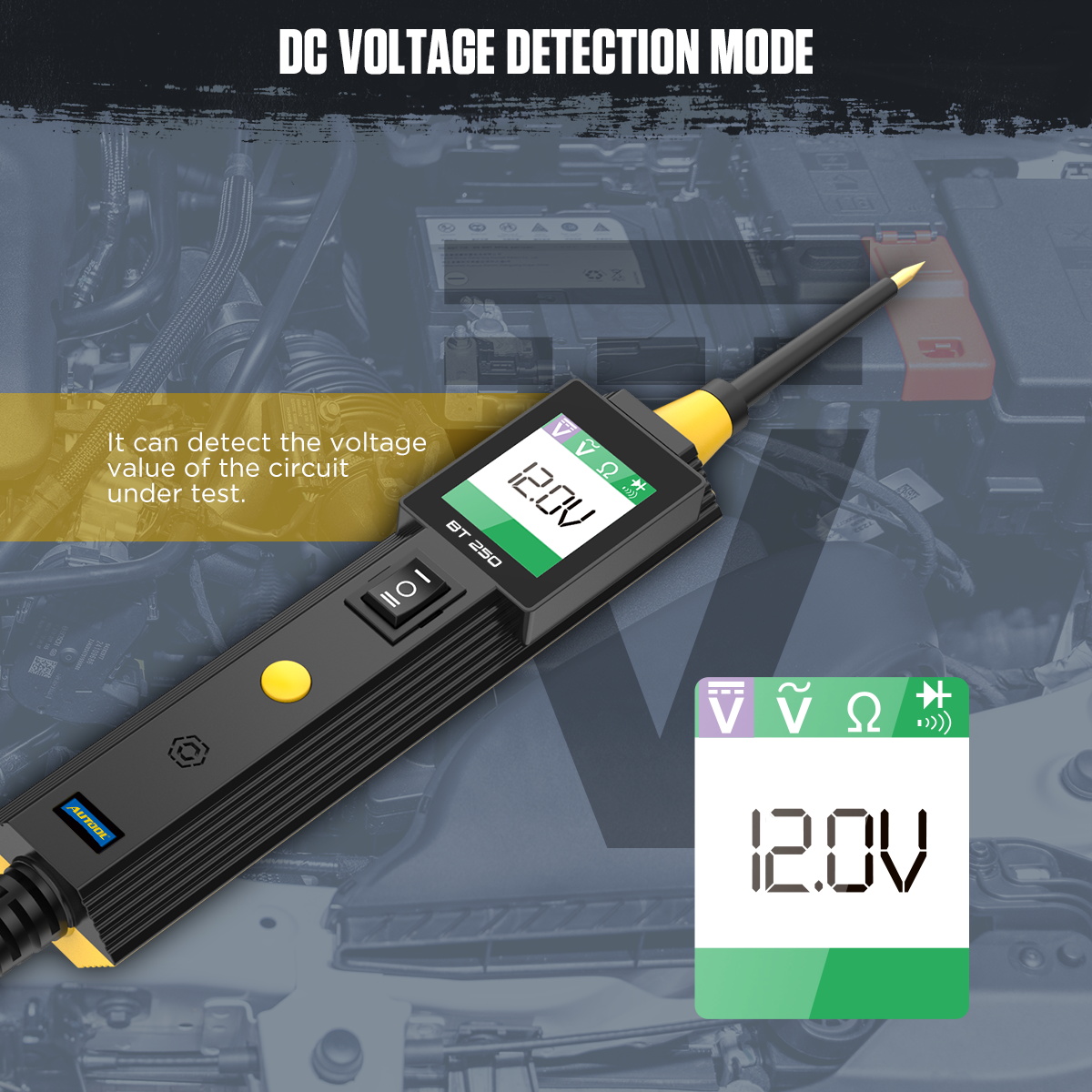

DC Voltage Testing: With a resolution of up to 0.1V and an accuracy of ±0.2V, it precisely measures the voltage values at various points in the vehicle’s electrical circuits.

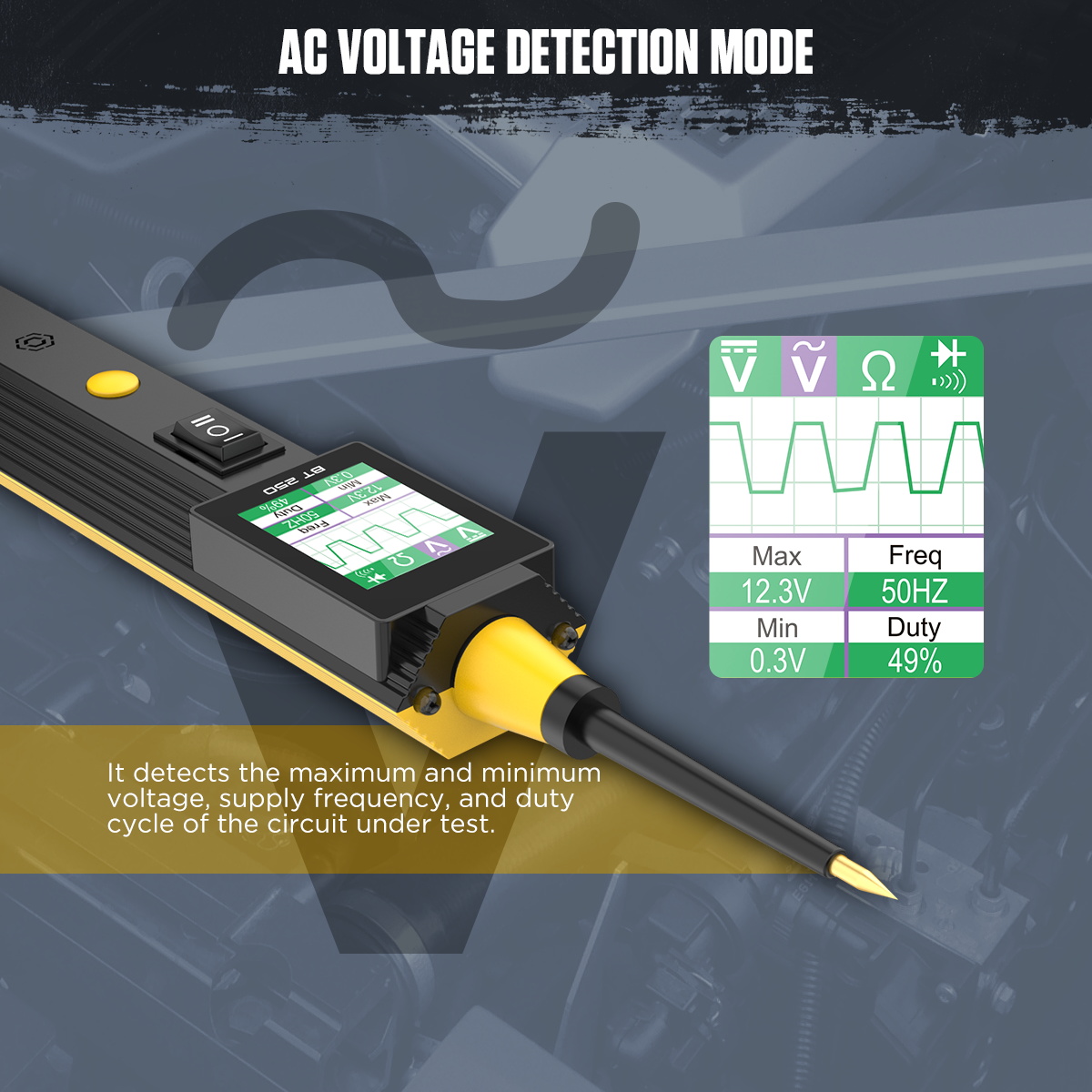

AC Voltage Testing: Capable of detecting the maximum and minimum voltage values of the tested circuit, as well as the power frequency and duty cycle.

Resistance Testing: Resistance range from 0 to 200kΩ, allows for measuring the resistance between the probe and the auxiliary ground wire of the tested circuit.

Diode Testing: Quickly tests the operational status of diode components and accurately checks for open circuits and continuity issues.

Backlit HD Color Display: Equipped with a 1.7-inch color screen that ensures clear visibility of test data, even in bright or dim environments.

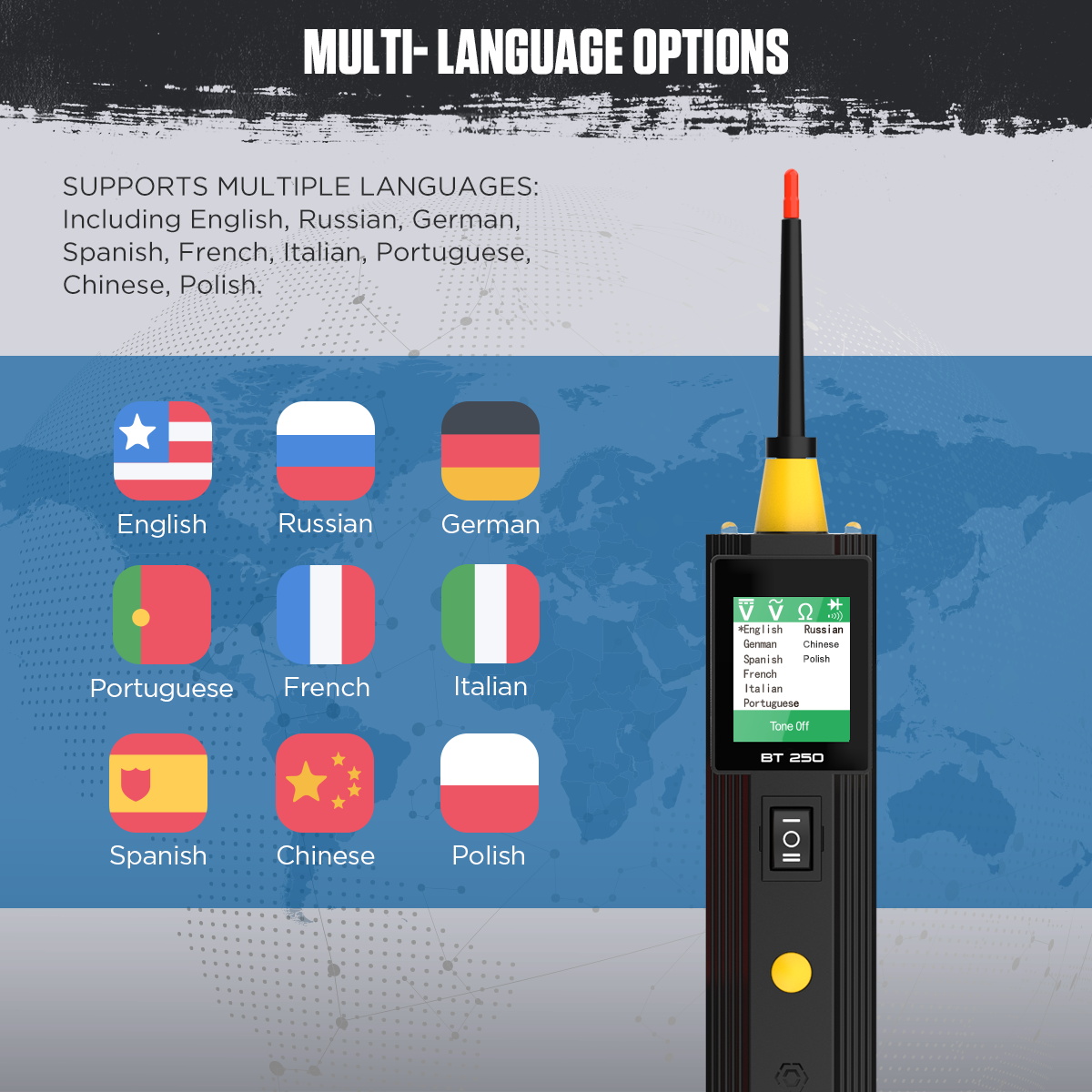

Multiple Language Options: Chinese, English, Russian, German, Portuguese, French, Italian, Spanish, and Polish.

Operating Instructions

Note: Upon initial use of the device, the buzzer will emit a “beep” sound, and the LED light will automatically turn on. You can toggle the light and buzzer on or off based on your actual needs. Before testing a circuit or component for the first time, please perform a self-check to ensure the circuit tester is in proper working condition.

Self-Check Procedure:

1. Connect the red clamp to the positive terminal of the car battery and the black clamp to the negative terminal.

2. Press the power button “-” to activate the probe with positive voltage. The LED indicator and screen will light up in red, and the screen will display 0.0V.

3. Press the power button “=” to activate the probe with negative voltage. The LED indicator and screen will light up in green, and the screen will display 0.0V.

4. If the above tests show normal results, the device is in good condition and ready for use.

Polarity Testing

1. Connect the red clamp to the positive terminal of the car battery and the black clamp to the negative terminal.

2. Short press the mode button to select DC voltage mode.

3. Touch the tip of the circuit tester probe to a contact point with an unknown polarity.

4. If the LED and screen on the circuit tester light up red and display a voltage value, it indicates that the contact point is positive voltage.

5. If the LED and screen on the circuit tester light up green and display a voltage value, it indicates that the contact point is negative voltage.

Continuity Testing:

1. Connect the red clamp to the positive terminal of the car battery and the black clamp to the negative terminal.

2. Short press the mode button to select resistance mode.

3. Touch the probe to the car chassis or an auxiliary ground line.

4. If the LED and screen on the tester light up green, and the display shows 0.0Ω, it indicates that the automotive electrical system is in a continuous state.

5. If the LED and screen do not light up green, it indicates that the automotive electrical system is in a broken state.

Signal Circuit Testing:

1. Connect the red clamp to the positive terminal of the car battery and the black clamp to the negative terminal.

2. Short press the mode button to select AC voltage testing mode.

3. Touch the probe to the car chassis or an auxiliary ground line, and connect the vacuum pump to the M.A.P. sensor.

4. Touch the circuit tester probe to the positive terminal of the M.A.P. sensor and

5. observe the waveform changes on the display screen (under normal conditions, the display should show a sine wave).

6. Start the vacuum pump.

7. Release the vacuum pump and observe the display screen reading.

8. If the screen shows an abnormal waveform, it indicates that the sensor is faulty.

Ground Fault Testing:

1. Connect the red clamp to the positive terminal of the car battery and the black clamp to the negative terminal.

2. Short press the mode button to select diode testing mode.

3. Press the “-” key on the tester. At this point, the tester’s LED and screen will light up red, and the metal probe will output positive voltage.

4. Touch the probe to the negative terminal of the component (the negative ground point), as close to the component’s terminal as possible.

5. If the ground is intact, the tester’s LED and screen will turn green.

6. If there is a ground fault or the test point is not grounded, the tester’s LED and screen will remain red.

Circuit Tracing:

1. Connect the red clamp to the positive terminal of the car battery and the black clamp to the negative terminal.

2. Short press the mode button to select diode testing mode.

3. Press the “-” key on the tester. At this point, the tester’s LED and screen will light up red, and the metal probe will output positive voltage.

4. Remove the faulty fuse from the fuse box and begin tracing from the load side of the fuse socket, making quick contact with the circuit points.

5. If the tester’s LED and screen turn green, it indicates a short circuit or an overloaded component in the current circuit.

6. Based on the measured wire color or code information, follow the direction of the wire harness or conductor to locate the next node position.

7. Disconnect the connection at that node and, in the same quick tapping manner, touch the circuit points before and after the node.

8. Confirm the direction of the fault and continue tracing. If a component is encountered, test it separately to check if it is intact, continuing until you trace to the end of the circuit, excluding the short circuit or overloaded component.

| BT250 | |

| DC Voltage Measurement Range | 0-65V |

| AC Voltage Measurement Range | 0~65V |

| Resistance Measuring Range | 0-200KΩ |

| Rated Current | 1-10A |

-

AUTOOL-BT250-BT260-MANUAL-.pdfDownload