Pneumatic Waste Oil Drainer Working Principle

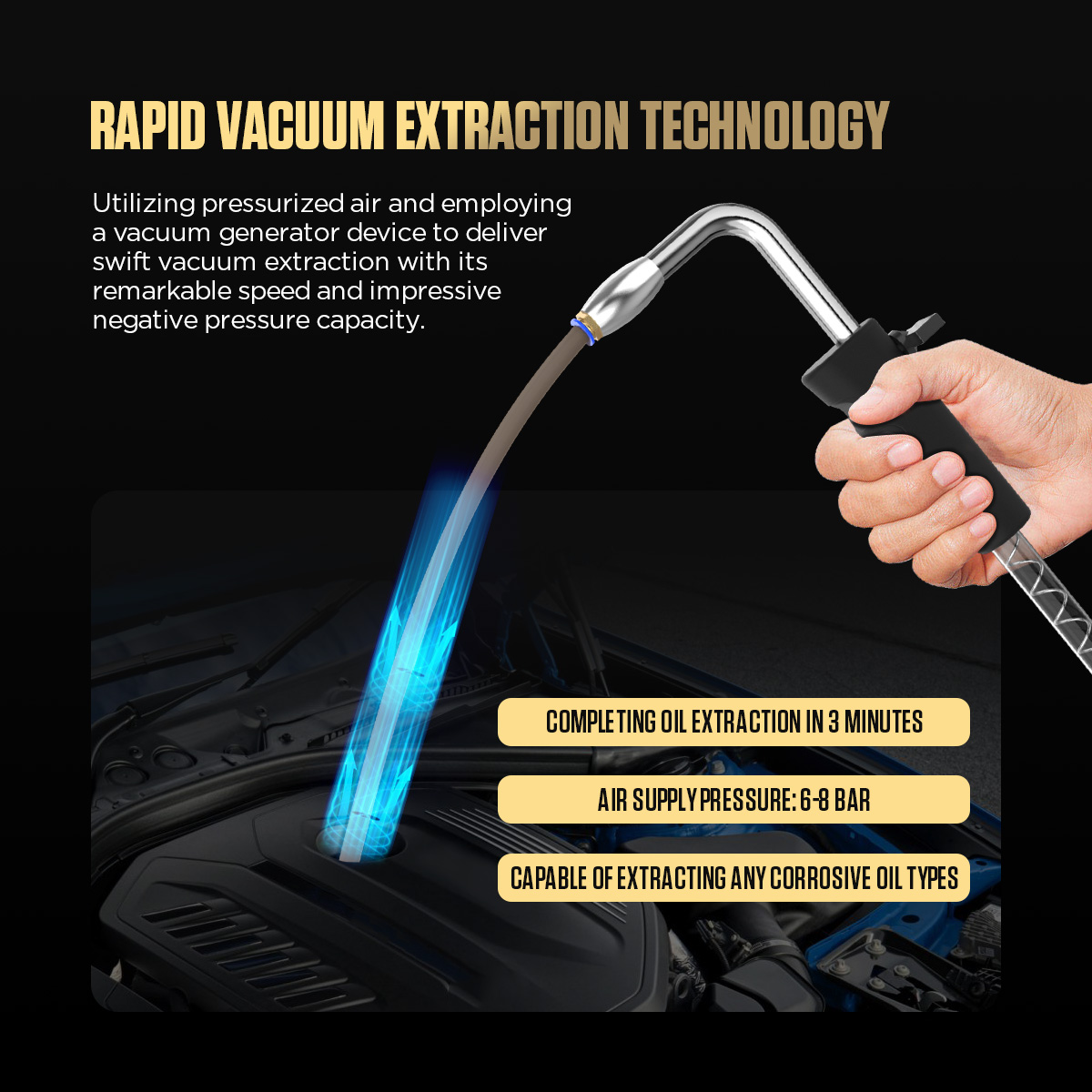

The Pneumatic Oil Extractor and Drainer uses compressed air to drive a vacuum generator, quickly generating strong negative pressure (approximately within 3 minutes), allowing for efficient oil extraction. This system utilizes pneumatic principles, providing not only powerful oil extraction capability but also ensuring safety and environmental friendliness during operation. Compared to traditional electric devices, the pneumatic system is more energy-efficient, effectively reducing energy consumption and meeting the low-energy requirements of workshop environments.

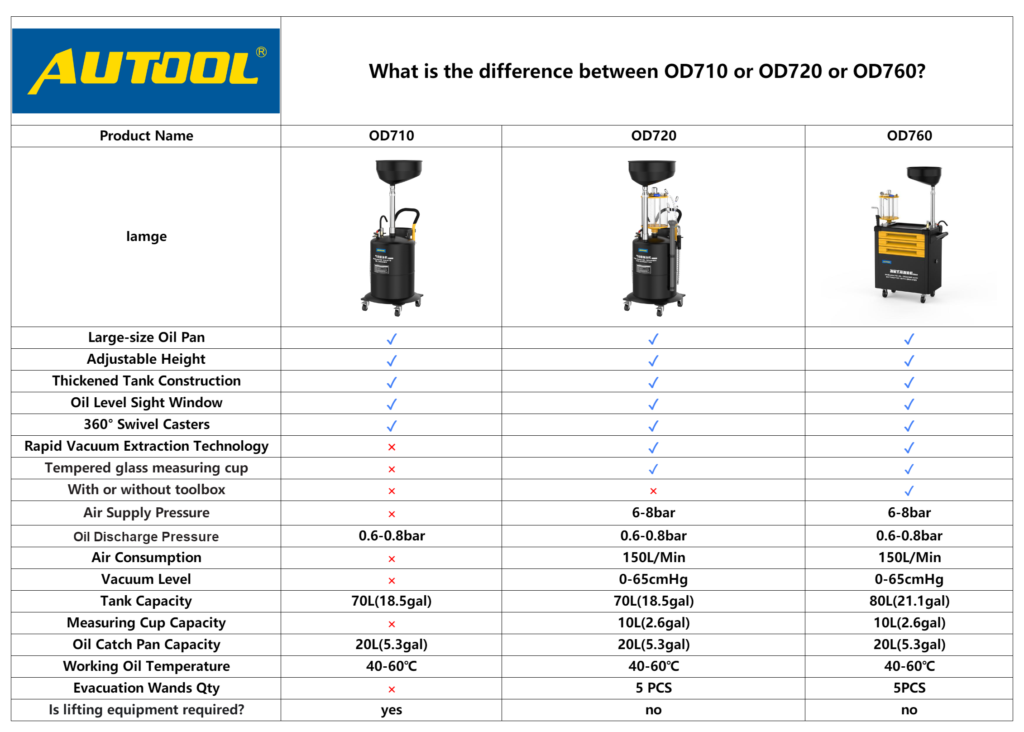

AUTOOL OD720 Pneumatic Oil Extractor And Drainer Features

Vacuum Oil Extraction Technology: Achieves rapid oil extraction in just 3 minutes, improving efficiency and output.

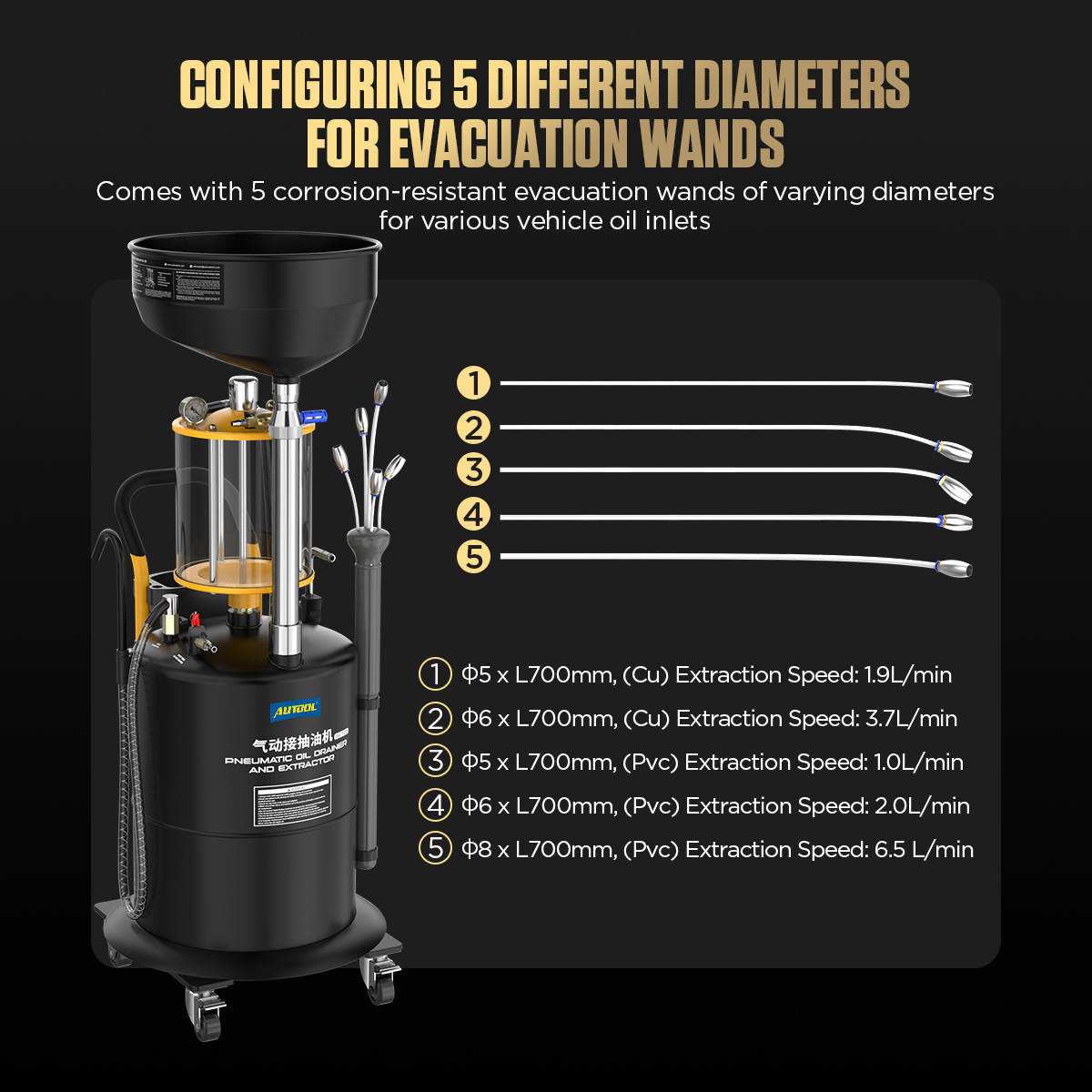

Five Vacuum Suction Tubes: Suitable for various vehicle models, offering multiple oil extraction methods.

Explosion-proof Tempered Measuring Cup: Features high temperature and corrosion resistance, suitable for storing various waste oils. The 10L graduated design allows maintenance personnel to easily observe the oil quality and accurately measure the oil volume.

70L Large Capacity: The approximately 20-gallon tank has a large capacity to hold waste oil, reducing the need for frequent emptying and improving work efficiency.

1.5mm Thickened Body: Ensures leak-proof and spill-proof performance, providing peace of mind during operation.

Large 20L Oil Collection Pan: With a diameter of 41CM, it provides a spacious oil collection area for easy operation.

Adjustable Height: Featuring a height-adjustable lifting rod structure, with a maximum adjustable height of 1.5 meters, allowing for flexible height adjustment as needed.

Oil Level Viewing Window: Equipped with an oil level viewing window to monitor waste oil recovery, making it easy to determine when to empty the tank.

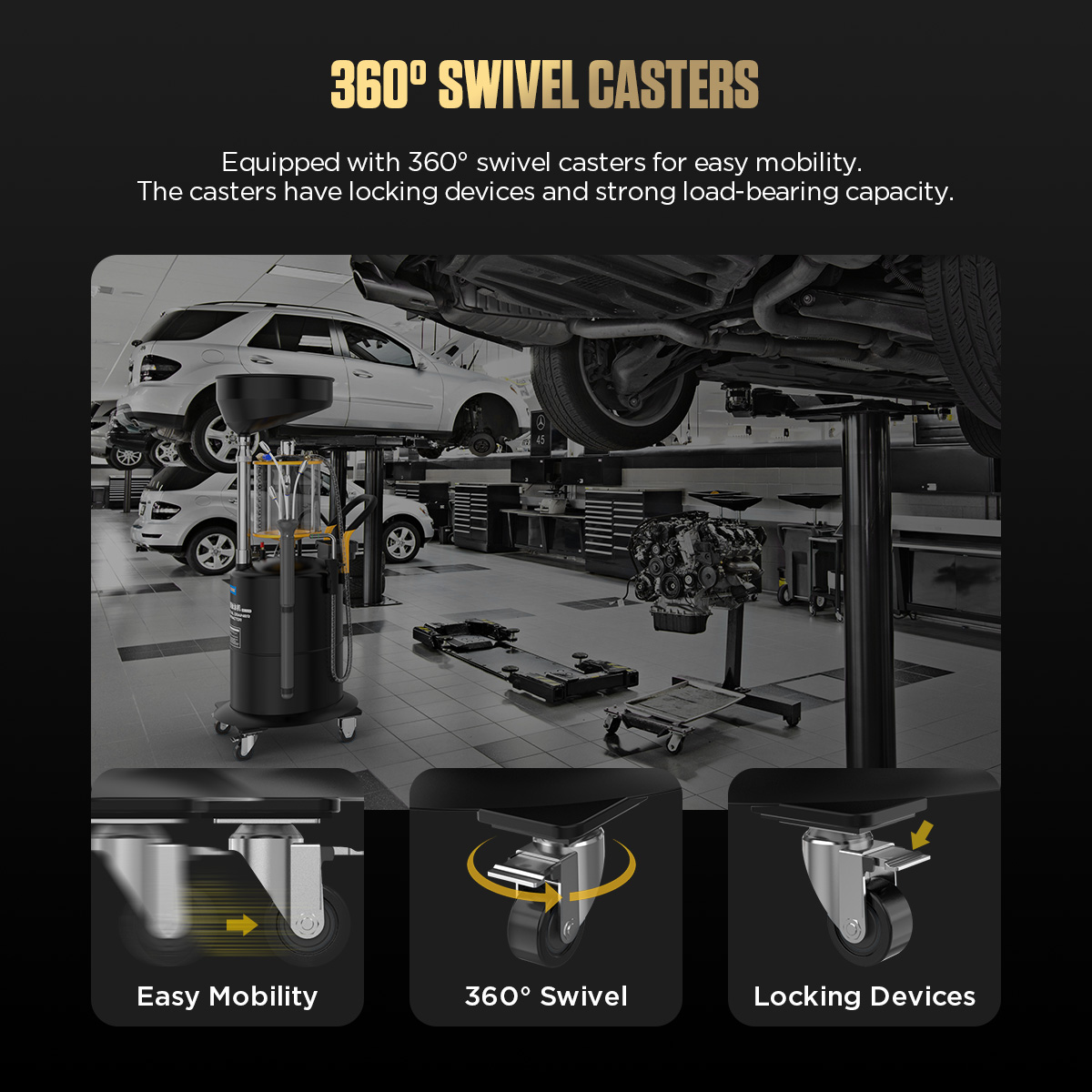

360° Swivel Casters: Fitted with 360° rotating casters for easy mobility, and the casters are equipped with a locking mechanism for enhanced load-bearing capacity.

Three-Year Warranty, Lifetime Maintenance: For damage caused by non-human factors, AUTOOL promises to resend parts for free within 3 years. If you have any problems, please contact us, and we will respond within 24 hours!

Specifications for vacuum tubes in 5 different diameters

Φ5*L700mm (Cu,1PC) Oil extraction speed:1.9L/Min

Φ6*L700mm (Cu,1PC) Oil extraction speed:3.7L/Min

Φ5*L700mm (Pvc,1PC) Oil extraction speed:1.0L/Min

Φ6*L700mm (Pvc,1PC) Oil extraction speed:2.0L/Min

Φ8*L700mm (Pvc,1PC) Oil extraction speed:6.5L/Min

AUTOOL OD710 Pneumatic Waste Oil Drainer

Operating Instructions:

Installation

1. Install the measuring cup assembly by rotating it in the clockwise direction onto the positioning seat of the oil storage tank.

2. Fix the lifting rod to the oil collection pan by rotating it in the clockwise direction.

3. Fix the measuring cup, ensuring that the assembly direction is correct.

4. After installation, please ensure that the lifting rod is in a vertical position relative to the device.

5. Rotate the lifting rod adjustment device counterclockwise to adjust the height of the lifting rod and the oil collection pan, and rotate clockwise to tighten it.

Measuring Cup Oil Extraction

1. Press the measuring cup and adjust the valve to the middle groove position (valve closed).

2. Close the oil suction hose valve and connect the appropriate suction needle.

3. Connect the air source to the intake port of the vacuum generator and open the air source valve.

4. The pressure gauge needle should move to the rated negative pressure of 50–65cmHg.

5. Insert the oil suction needle into the engine compartment, open the oil suction hose valve, and extract the waste oil.

Draining Waste Oil from the Storage Tank

1. Close the oil drain valve.

2. Close the air inlet valve of the oil tank.

3. Connect the air supply to the air inlet valve of the oil tank.

4. Open the air inlet valve of the oil tank to pressurize the tank. Once a certain pressure is reached, the check valve will automatically close. If the pressure inside the tank exceeds 1.0 bar, the safety valve will automatically release the pressure.

5. After 5 seconds, slowly open the oil drain valve to discharge the oil.

6. Once the oil has been drained, please disconnect the air supply.

Note:

1. The air compressor must maintain a stable pressure of 7 bar.

2. Handle the extracted waste oil (40°C~80°C) with care to avoid burns.

3. When the waste oil temperature exceeds 60°C, it may cause damage to the equipment components!

4. Always turn off the engine switch during operation.

5. Avoid extracting gasoline, diesel, liquids containing methanol, ketones, or flammable substances.

6. After using the pneumatic waste oil drainer, please release the pressure inside the equipment, clean it properly, and ensure proper handling to prevent equipment damage and personal injury caused by improper operation.