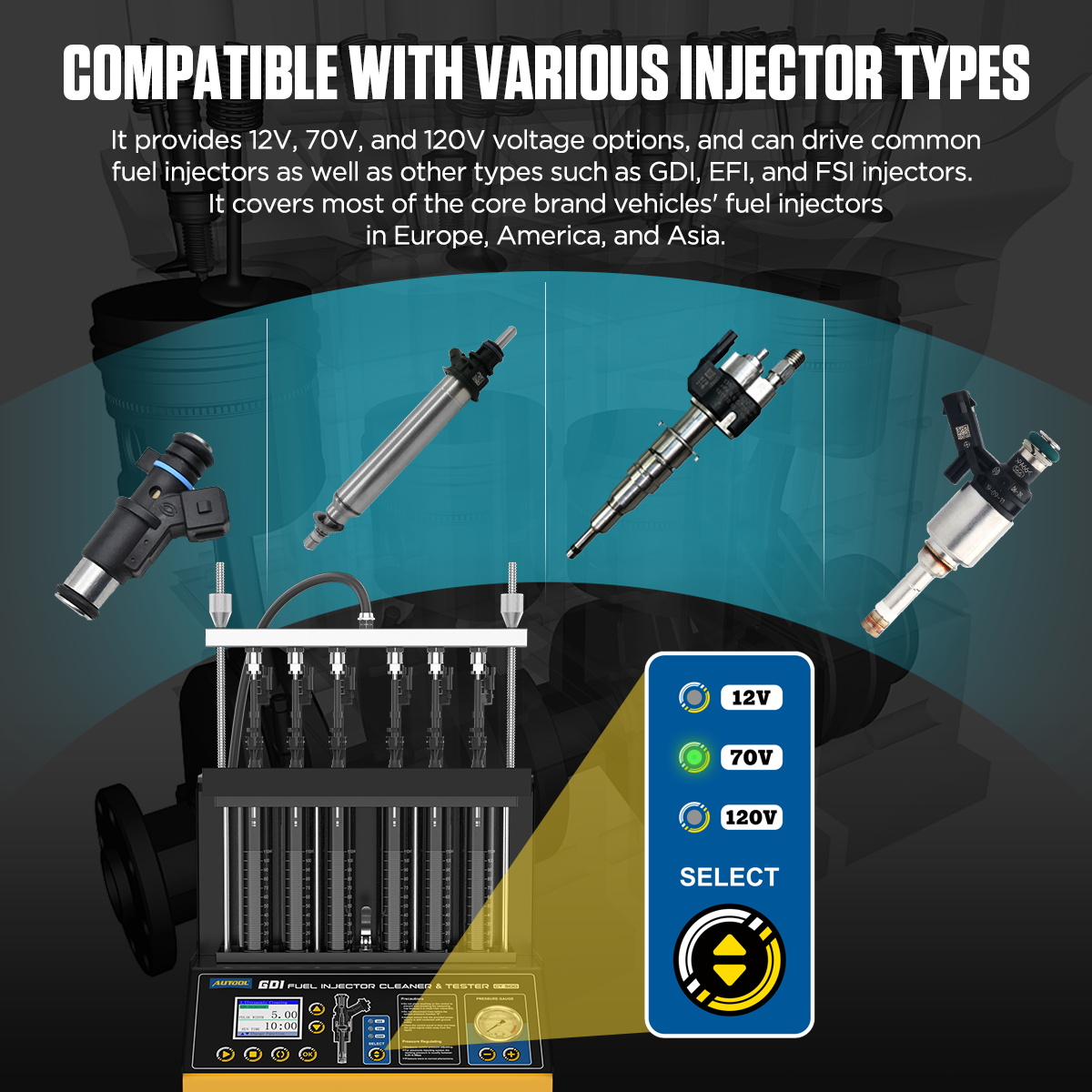

The AUTOOL CT500 GDI Fuel Injector Cleaning Machine utilizes advanced GDI injector driving technology, precisely simulating the operation of gasoline direct injection (GDI) engines. GDI involves injecting fuel directly into the cylinder, where it mixes with intake air. Compared to traditional injection systems, this not only significantly enhances engine efficiency and power output but also effectively reduces exhaust emissions. The CT500 is equipped with an integrated GDI injector driving system that supports the cleaning and testing of various injector types, including GDI, EFI, FSI, and standard injectors. The equipment offers three voltage driving modes (12V, 70V, 120V) to meet the diverse needs of fuel injectors from mainstream automotive brands in Europe, America, and Asia, showcasing excellent compatibility and performance advantages.

AUTOOL CT500 Fuel Injector Tester & Cleaner Features

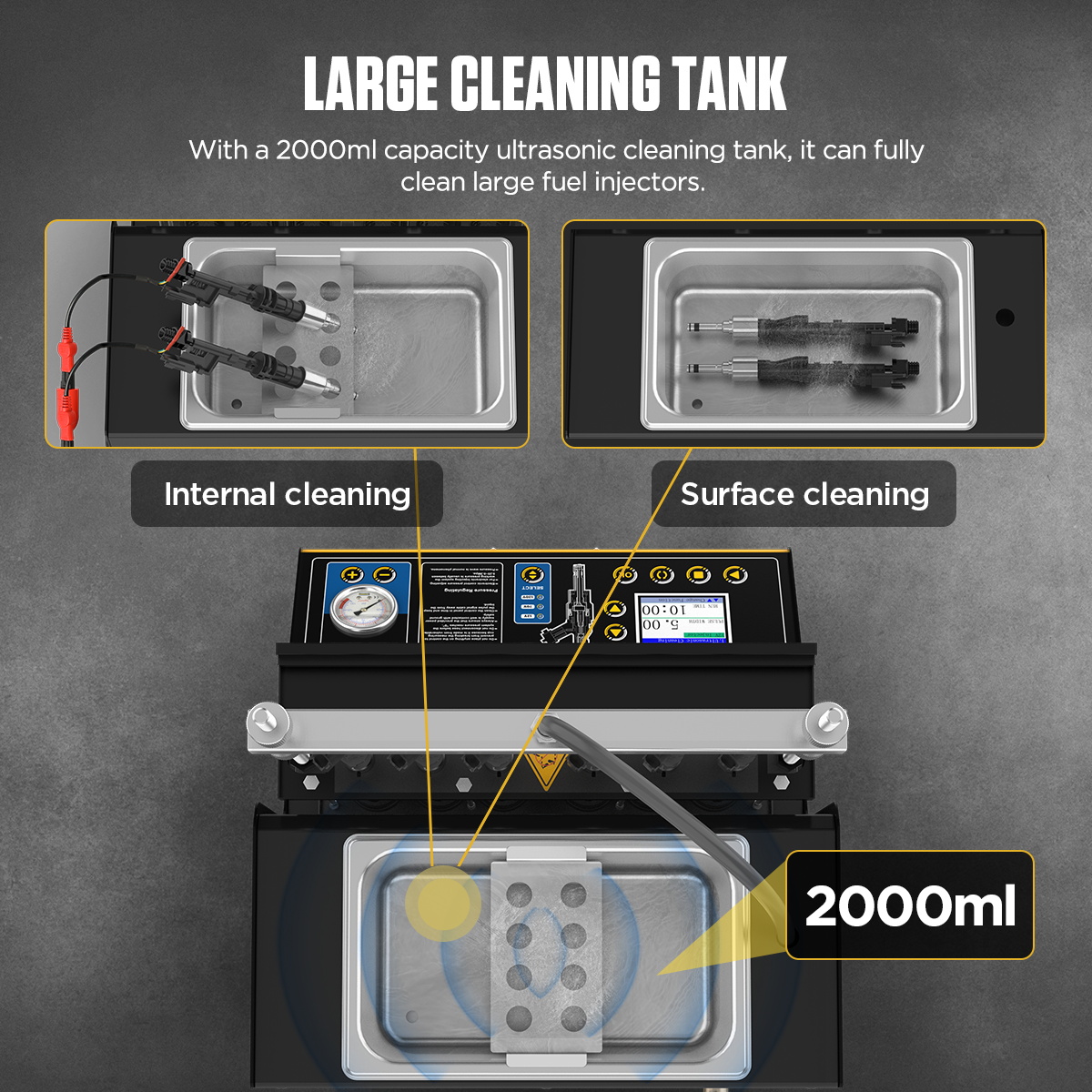

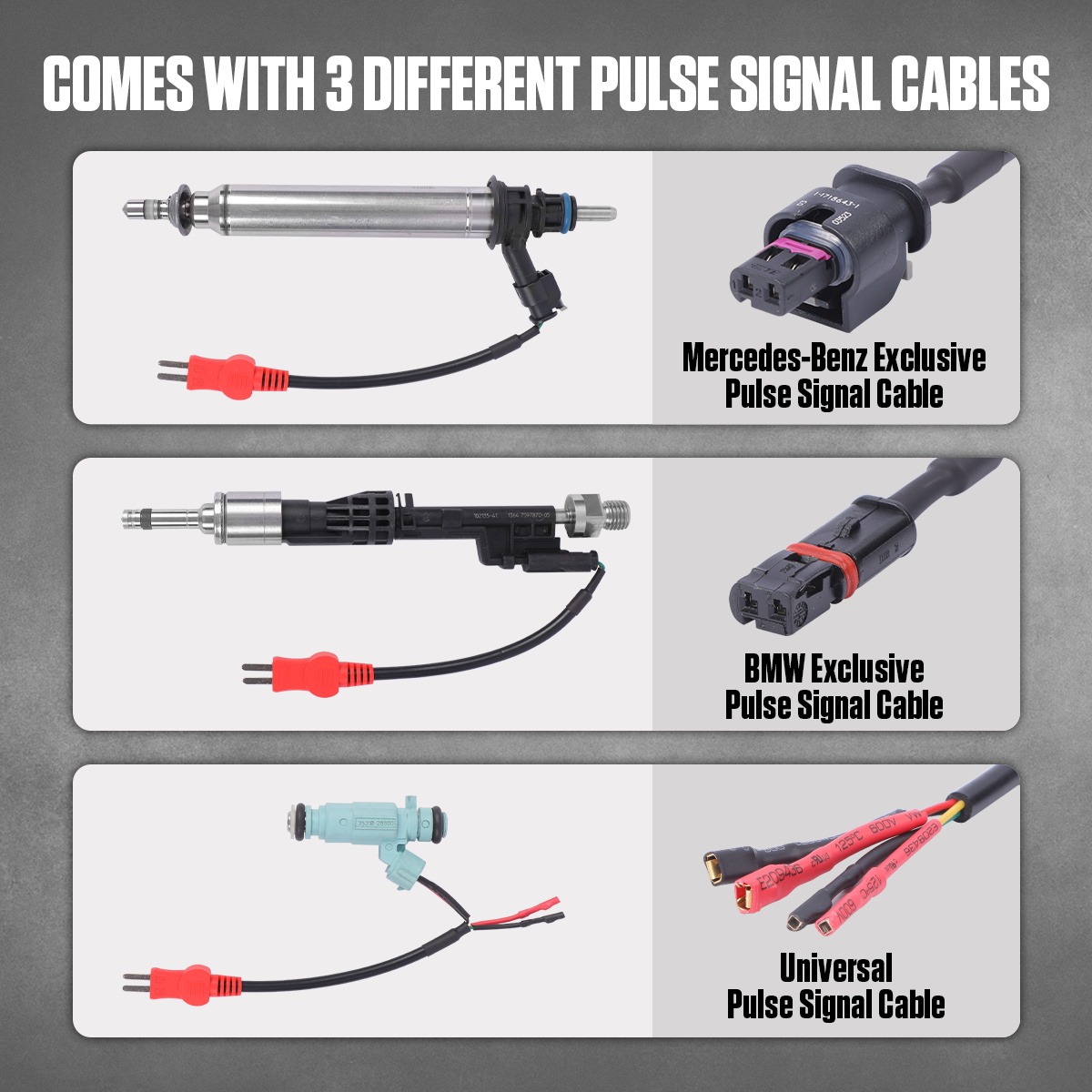

Ultrasonic Deep Cleaning: The CT500 GDI fuel injector cleaning machine sends signals to the fuel injectors through pulse signal wires. Combined with cleaning fluid and ultrasonic vibration technology, it efficiently removes carbon deposits and stubborn impurities inside the injectors, ensuring thorough cleanliness.

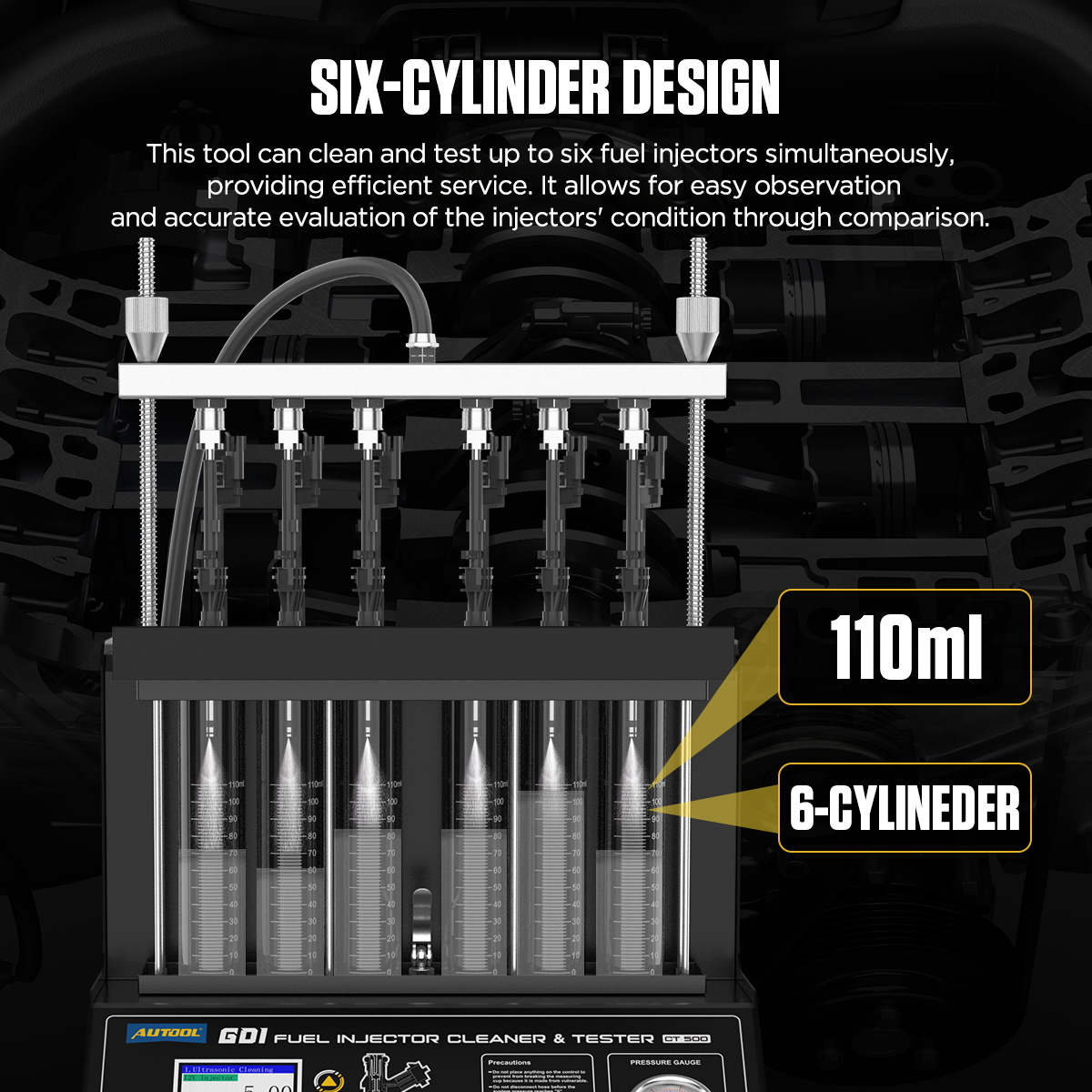

Multi-Injector Cleaning and Testing: The CT500 Fuel Injector Tester & Cleaner is equipped with 6 independent glass tubes, allowing for the simultaneous cleaning and testing of up to 6 injectors. This significantly enhances cleaning efficiency, simplifies the testing process, and makes operation more efficient and convenient.

Reverse Flushing Function: The AUTOOL CT500 GDI fuel injector cleaning machine utilizes cleaning fluid injected in reverse from the injector outlet to the inlet, effectively removing internal carbon deposits and filter impurities. It is especially suitable for top-feed fuel injectors, greatly enhancing the cleaning effect (only applicable to top-feed fuel injectors).

Non-disassembly Cleaning Function: With the help of a dedicated adapter, the fuel injectors can be cleaned directly without disassembly, making it convenient and quick, offering an additional cleaning option (this function requires the optional non-disassembly cleaning tool).

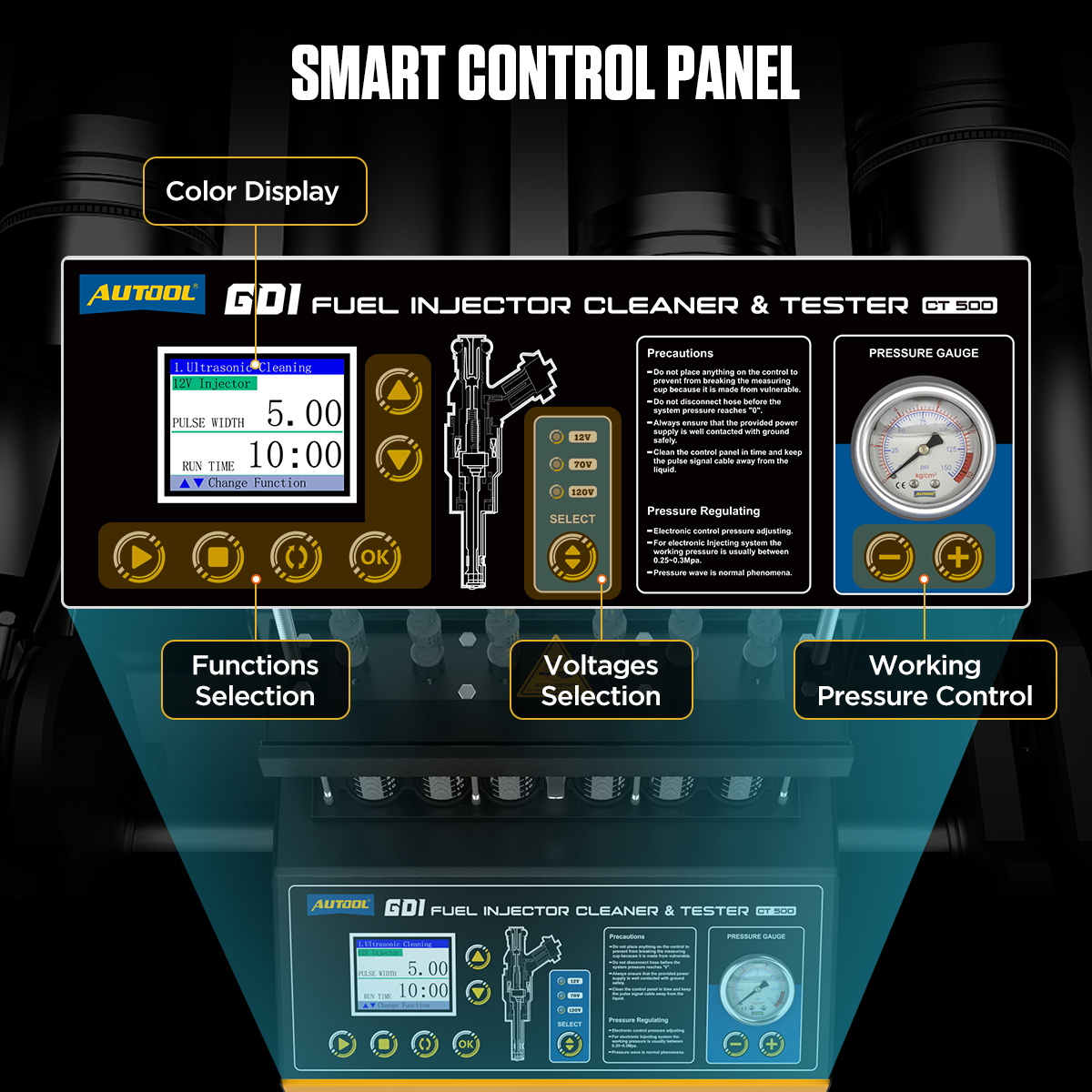

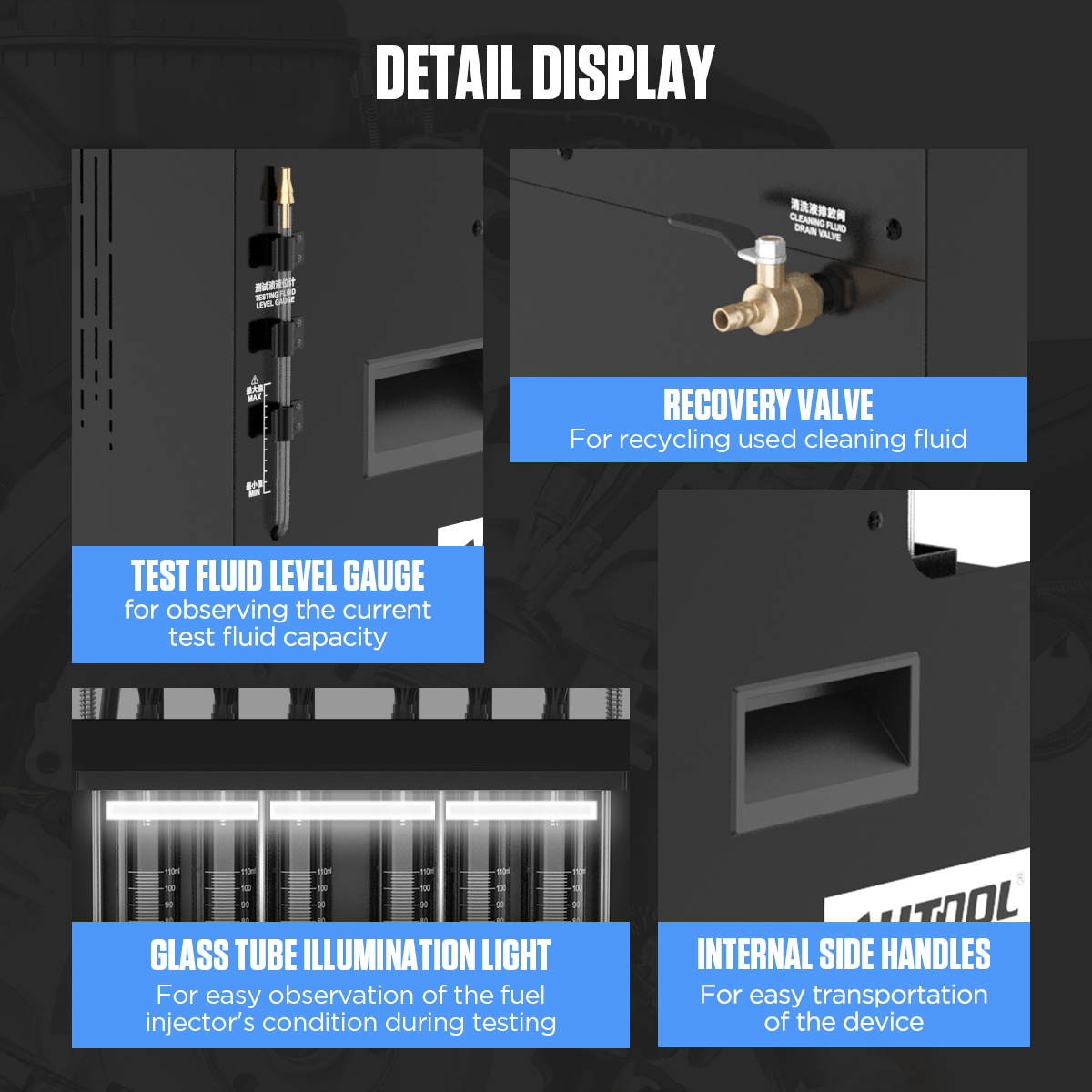

Intuitive Display Function: Equipped with a level gauge, it accurately shows the amount of test fluid added, ensuring precise test results. The pressure gauge continuously monitors the test pressure, effectively preventing excessive pressure from damaging the equipment or injectors, making the operation safer and more reliable.

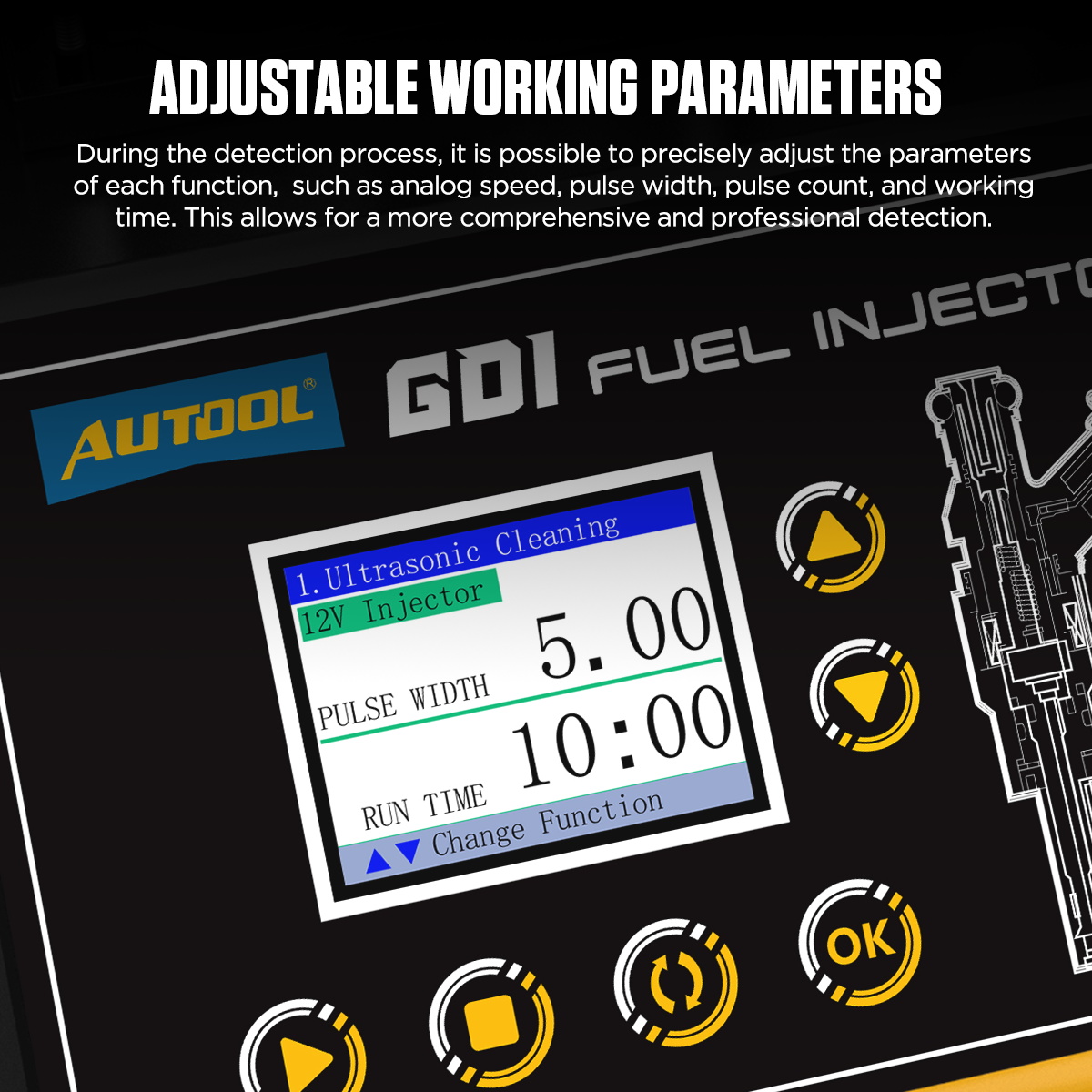

TFT Color Display: Equipped with an HD TFT color display, it presents clear and detailed data in various environments, offering intuitive and convenient operation that greatly enhances the user experience.

Dual Language Switch: Supports both Chinese and English language modes, making it convenient for users in different regions and meeting global usage needs.

Convenient Liquid Recovery: Equipped with a cleaning fluid recovery valve for collecting used cleaning fluid, and a liquid level gauge to monitor the recovery (once the liquid level drops, the fluid can be recovered). This effectively prevents potential damage to the equipment caused by prolonged liquid residue. The recovered fluid can be reused, protecting the equipment and reducing operating costs, making it both economical and environmentally friendly.

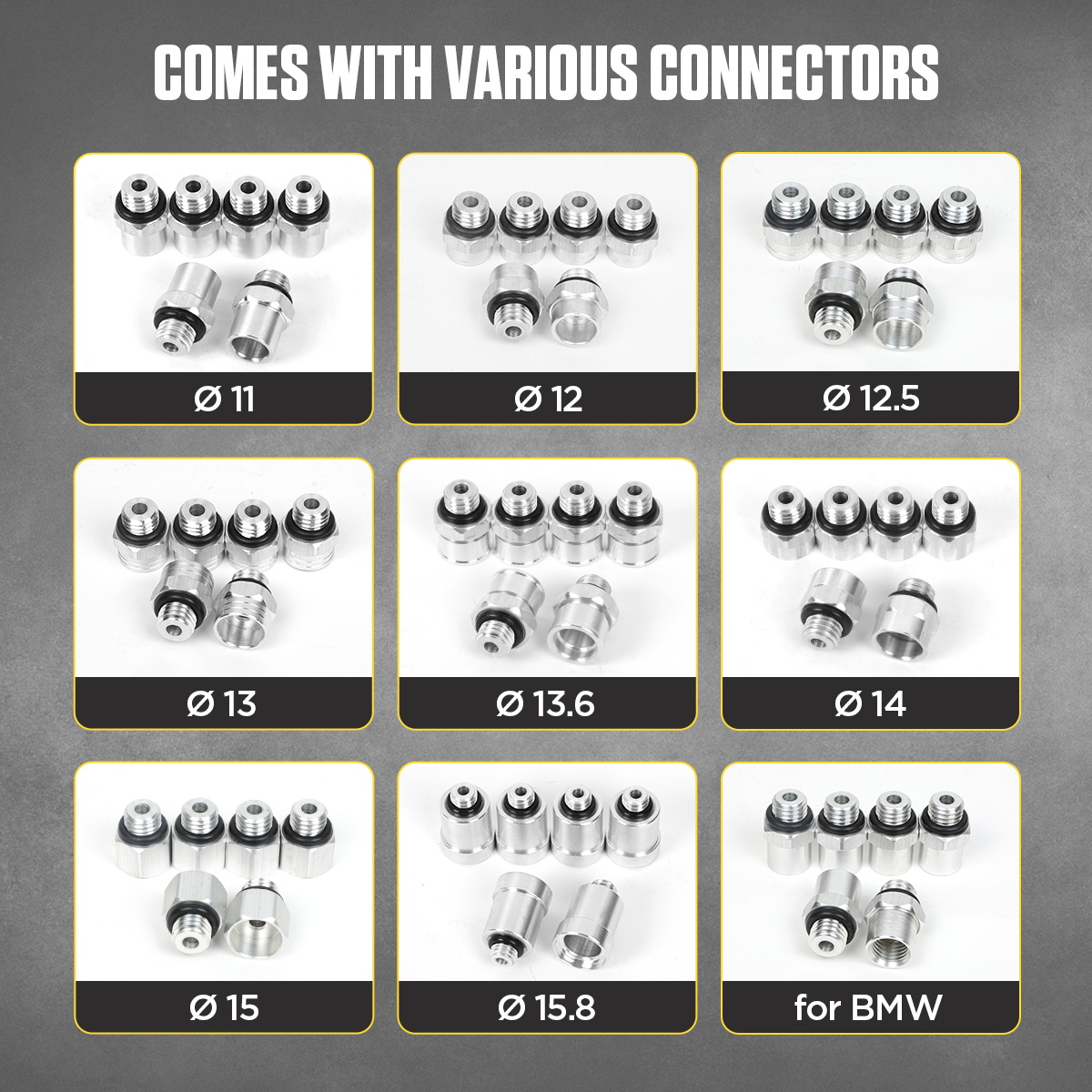

Wide Compatibility: Compatible with various types of fuel injectors, including GDI, EFI, FSI, etc. It supports cleaning and testing of both standard injectors and three voltage driving modes (12V, 70V, 120V), providing professional solutions for the majority of vehicle models on the market.

Convenient Storage: Equipped with a built-in small drawer to neatly store various fuel injector adapters, making them easy to access and effectively preventing parts from being lost. The thoughtful design makes you more worry-free. The side of the equipment features an embedded handle, enhancing portability, making movement easier and operation more comfortable.

Three-year Warranty: For damages caused by non-human factors, AUTOOL promises to provide free replacement parts within three years. If you have any requests, please feel free to contact us, and we will respond promptly within 24 hours.